best practices

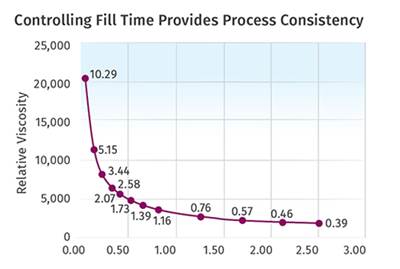

INJECTION MOLDING: Get Control Over Barrel Zone Temperature Override

Poor temperature control results in an erratic melt stream and process. Here are some tips on how to get things under control.

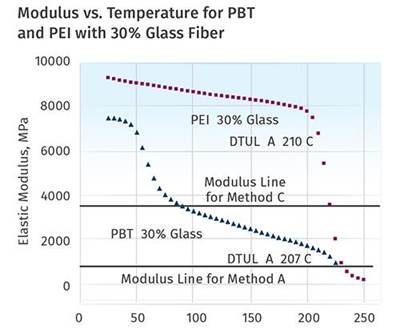

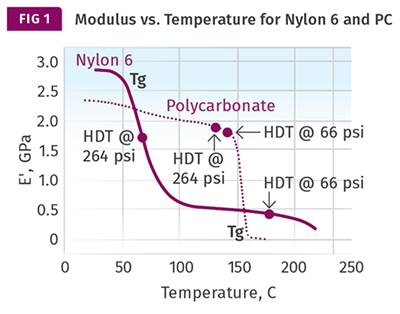

Read MoreMATERIALS: The Problems with Single-Point Data, Part 8

DTUL tests may have made sense in the 1940s and 1950s, before the advent of dynamic mechanical analysis. But designers and engineers today need better tools.

Read MoreTOOLING: Designing Molds for Easy Maintenance in the Press, Part 1

Attention to design of cooling, ejection, and slides can save downtime and maintenance headaches.

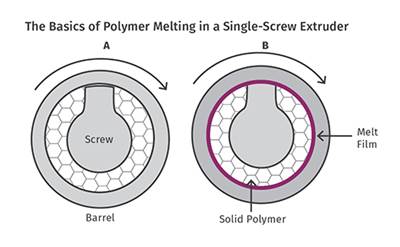

Read MoreEXTRUSION: Melting 101

Learn the basics on how polymer melts in a single screw. Barrel temperature plays less of a role than you might think.

Read MoreINJECTION MOLDING: Develop Guidelines—Not Strict Procedures— For a Robust Molding Process

‘Fool-proof’ dos and don’ts will prove foolhardy in a process with so many variables. You aren’t slinging burgers.

Read MoreMATERIALS: The Problems with Single-Point Data, Part 7

The industry can choose between continuing to perform DTUL tests that provide single points that are part of a curve never seen, or perform the test that provides the entire curve.

Read MoreMolder Expands Plant, But That’s Just the Beginning

Wescon cuts ribbon on a new addition and adds presses as part of a strategic plan to double its business.

Read MorePellet Production Is a Blast For This Processor

Maxi-Blast opens a plant with brand-new equipment to produce its own pellet blasting media.

Read MoreGet Back to Basics On Water-Cooling Equipment

Neglecting your plant water systems can result in inefficiencies and downtime. Follow these tips when you get new equipment on stream or to maintain what you’re already running.

Read MoreDown in the Valley, Profiles Grow

Valley Extrusions carves niche in tight-tolerance, short-run tubing and profiles.

Read More