Compounding

Mixing Systems for Ultra-High Viscosity Materials

Double Planetary Mixers are well suited for mixing thick, sticky, or putty-like materials.

Read MoreProgram Helps Compounders Configure Screw, Barrel Layout

New software from ENTEK is said to make it easier for compounders to design their own screw and barrel configurations.

Read MoreHow to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreMulti-Agitator Mixing System

Operators can monitor key parameters in real-time through a 7-in. color touch screen interface.

Read MoreMore Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

Read MoreExtruder Builder ENTEK Starts Wear-Parts Division

Division will make replacement wear parts for all twin-screw extruder brands. Tammy Straw named director.

Read MoreCompounder Adds Capacity, Capabilities in Rochester

Enhancements to plant said to help compounder meet production and sustainability goals of customers.

Read MoreMulti-Shaft Mixers for Medium- to High Viscosity Applications

Range from laboratory to large scale capacities up to 4000 gal.

Read MoreHillenbrand Buys Schenck

Materials handling and feeding company to join forces with Coperion/Coperion K-Tron.

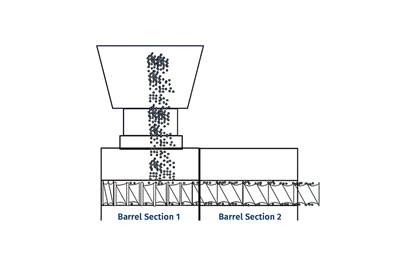

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read More