Compounding

Next-Generation Pelletizers

Bay Plastics Machinery Inc. (BPM) will be unveiling what it calls the next generation of pelletizing technology at K 2022 in Düsseldorf, Germany.

Read MoreHigh-Dispersion Rotor for Compact Processor

Billed as ideal for processing fiber grade, high color carbon black, and color concentrates.

Read MoreGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

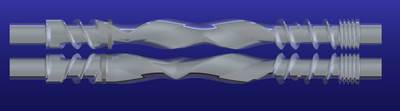

Read More10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Read MoreSystem Improves Pellet Cooling

Billed as especially suited for high melt index or peroxided polymers.

Read MoreMixers Restored to Like-New Condition

Refurbishing services from ROSS offers users reconditioned mixers that are comparable, if not equal to, brand new equipment.

Read MoreReworking Off-Spec Material? Add Some Science to the Mix

Reworking off-specification material and low-demand material is good for the compounder and good for the environment. Here’s how to make sure it’s good for the customer too.

Read MoreLFT-D Thrives in Automotive and Other Durables

Teijin Automotive acquires its 10th direct long-fiber thermoplastic system as demand for this technology soars.

Read MoreENTEK Manufacturing Names Three New Vice Presidents

Extrusion machine builder promotes three veteran employees.

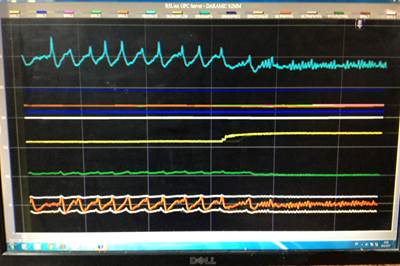

Read MoreStrategies for Solving Process Problems in Twin-Screw Compounding

When investigating compound quality defects or determining the root cause(s) of processing problems, look for spatial and/or temporal patterns to provide clues. The strategy to identify an assignable cause and cure is to first determine whether the problem is chronic or transient.

Read More