End Markets

MGS Creates Healthcare Center of Excellence in Wisconsin

The supplier of tooling, molding and assembly equipment is investing $20 million in its Germantown site, adding a Class 8 cleanroom and 20 presses, while consolidating its Illinois molding operations.

Read MorePoland Spring to Use 100% Recycled Plastic by 2022

However, as recycling rates in the United States still hover around 30%, Poland Spring recognizes that in order to fulfill its commitment to use recycled plastic in its packaging, it must also invest in recycling initiatives.

Read MoreNylon 66 Replacement With the Aid of a Materials-Savvy Distributor

PolySource helped two OEMs—one in beverage packaging, the other in winter sports vehicles—transition from nylon 66 to polyketone (POK) compounds after parts failure.

Read MoreWater Injection Beats Gas Assist in Lightweighting Car Door Panel

Renault’s conversion from metal-frame construction to plastics prototype switched from gas assist to water injection. Here’s why and how.

Read MoreHow to Manage Pressure Loss in Injection Molding

Achieving a process window wide enough to ensure consistent part quality depends on achieving sufficient pressure at end of fill.

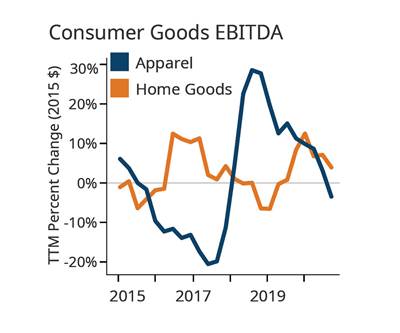

Read MoreConsumer Products: A Tale of Two markets

The home goods portion of the consumer products industry is growing. Not so with apparel.

Read MorePlacing a Bet on Bioplastics

Steinwall has put years of R&D into learning to design and mold with biopolymers and natural-fiber reinforcements. Now that groundwork is beginning to pay off.

Read MoreGiving the ‘Royal’ Treatment in PET Packaging

In the U.S. for just seven years, Royal Interpack is emerging as a growing, innovative, customer-centric supplier of food packaging.

Read MoreDiagnosing the Medical Market

Michael Guckes, chief economist for Gardner Intelligence, will analyze the medical device industry using a unique three-pronged approach at the Medical Injection Molding Workshop during Amerimold.

Read MoreNew PLASTICS Report Shows Viable Market for Recycled Plastic Bumpers

Launched in 2015, the ELV Project was designed to study the viability of collecting and recycling plastic car parts, including car bumpers, to eventually be broken down and used as materials to make new products.

Read More