Extrusion

Central or Portable? Flexibility Favors ‘Discrete’ Chillers

Why might discrete chillers be a solution in your plant? In a word: Flexibility. Here is the lowdown.

Read MoreSoak Time and Plate Out Best Practices

What is the ideal soak time for a cold start up of an extruder, especially if there's material in the die and what kinds of resins can lead to plate out?

Read MoreBenchmark Your Extruders For Quicker Processing Fixes

Not recognizing output reductions and resolving them quickly can cost a lot of money. Benchmarking your machines will help.

Read More'Beastly' Line Adds Sheet Extrusion Flexibility

They call it the “The Beast,” a new sheet line installed recently by custom extruder Rowmark in Findlay, Ohio (rowmarkllc.com). It’s nearly as long as the new 175 x 75 ft facility built to house it.

Read MoreExtrusion & Injection Molding in One Automated Process

A large German manufacturer of hoses, cable ducts, and other extruded automotive components recently expanded its activities into the white-goods appliance sector.

Read MoreOn Site: Pexco Takes a Two-Pronged Approach to Growth

Organic growth and growth via acquisition have combined to make this processor one of the leaders in custom profile extrusion.

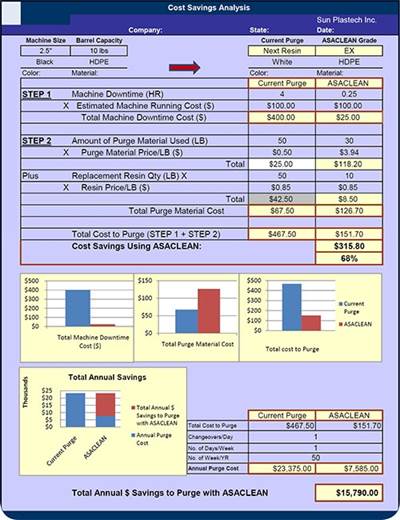

Read MoreHow to Use Commercial Purging Compounds in Extrusion

CPCs are considered most often for injection molding. However, they also can provide the same benefits to extrusion processors.

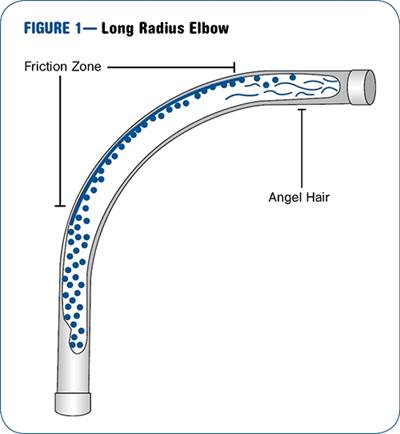

Read MoreAvoid Those Devilish ‘Angel Hairs’

Angel hairs wreak havoc on plastics processing: clogging filters, plugging conveying lines, causing feed problems at the blender, and jamming up machine throats. Here's how to prevent their formation.

Read MoreNew Die Opens Up New Markets

General Plastic Extrusions Corp. found that out recently in converting a second-hand blown film line that had been used by its previous owner for R&D.

Read MoreThe Truth About Barrel Heating

The main purposes of the heaters are to melt the polymer that remains in the barrel at cold startup, to assist in forming the initial melt, and to “trim” the barrel temperatures for specific purposes such as improving feed rate.

Read More