Extrusion

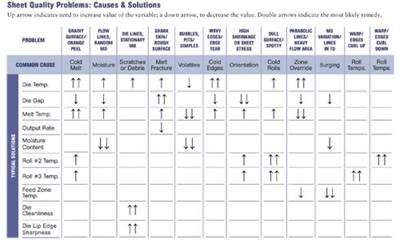

Follow This Action Plan to Keep Your Sheet Dies in Line

Getting back into production after maintenance or troubleshooting requires a coordinated effort. Here’s how to get your sheet line up and running as fast as possible.

Read MoreProcessor Strategies - Royal Group Profile Maker Gives Environment The ‘Royal’ Treatment

When you’re already a leader in your industry, you might be tempted to simply stay the course and not worry about issues such as sustainability and carbon footprint.

Read MoreExtrusion: Why Is Material Backing Up Into the Feed Throat?

Could starve feeding be the cause of material not moving through the feed section and backing up into the feed throat of an extruder?

Read MoreTooling: More Is Better…Layers, That Is

I can’t count the number of times I have been asked why I recommend a blown film line with 5+ layers to make 2- or 3-layer products.

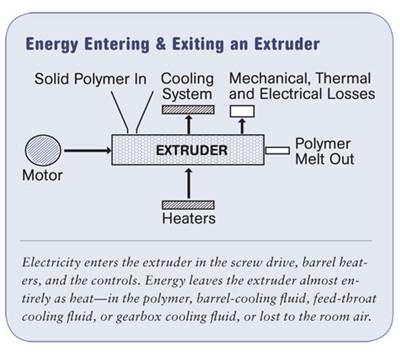

Read MoreExtrusion: Reducing Energy, Part II: ‘Adiabatic’ Extrusion

The term adiabatic extrusion was very popular in the ’60s and ’70s, but has seemingly disappeared from the processing terminology of today.

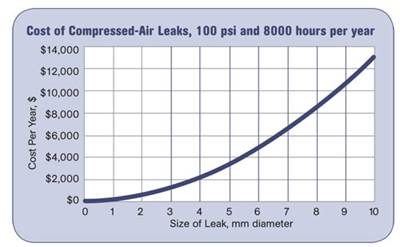

Read MoreEnergy Miser: Plug Costly Compressed-Air Leaks

Last month we introduced the idea that compressed-air usage is one of the first places any manufacturer should look to reduce energy cost.

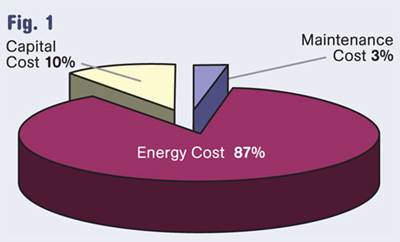

Read MoreTips and Techniques: Boosting Extrusion Productivity - Part III of III: Trim Your Material & Energy Costs

Material cost is the largest cost factor in most extruded commodity products, so processors should be motivated to reduce these expenses.

Read MoreExtrusion: Run Your Chevy Volt with Extruder Energy Savings—Part I

The electricity saved on a large extrusion line could power a number of Chevrolet Volts.

Read MoreCompressed Air Isn’t Free!

Compressed air is a convenient and often essential utility, but it is very expensive to produce, and most of the energy used to compress air is turned into heat and then lost to the system and environment.

Read MoreExtrusion: Multi-Pass Tubing Tank Offers Higher Quality, Resin Savings

A new cooling and sizing tank for extruded tubing reportedly allows processors to reduce wall-thickness tolerances and cut material use dramatically while increasing productivity and reducing floorspace requirements.

Read More