Injection Know How

How to Specify A Resin Dryer

To dry your polymer correctly you need a dryer that is properly designed and working properly. Here are my suggested specifications, for a two-, three- or four-bed desiccant dryer, the most common types used.

Read MoreTop 10 Reasons Why Molders Fail At Implementing ‘Scientific Molding

What is Scientific Molding? And why do molders seem to have such a difficult time embracing its concepts? Here are some thoughts on the matter.

Read MoreGet the Most From Your Tooling

The history and culture of the molding industry has been to pull out every trick possible to work around design, resin, tooling, processing, and testing issues once the mold arrives. It is time to rewrite history.

Read MoreEstablish a True ‘24/7’ Production Process

New or existing mold trials need to produce a production-worthy process that will run 24/7.

Read MoreNozzle Leaks: Why They Occur, How to Detect & Fix Them

Nozzle leaks are a serious problem in injection molding. Here are some causes and remedies.

Read MoreShould You Profile Injection Velocity?

If you can get by with one velocity, use only one, because fill time is easier to reproduce, and it is easier to set up the process.

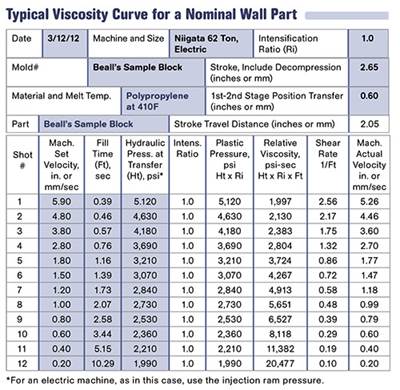

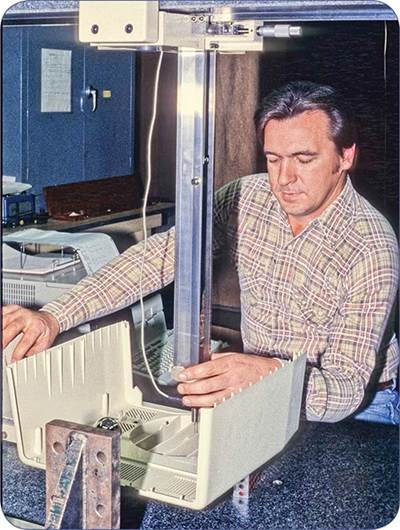

Read MoreUnderstanding Polymer Flow: Interpreting the Viscosity Curve

Take the time to do the viscosity curve on new molds. You will learn more in that hour than many learn in years about the process for this tool.

Read MoreGetting Good Data from DOE

How do you know what process variables control a part’s dimensions or other properties? A properly conducted DOE is the answer—but incorrect procedure will yield useless data.

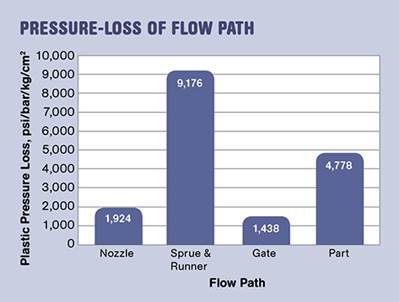

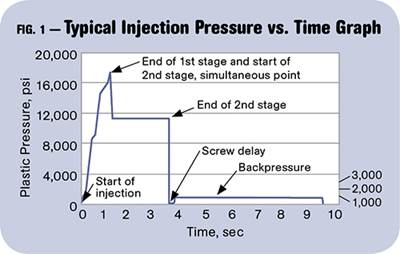

Read MoreImprove Profits by Graphing Injection Pressure

Graphing is a powerful aid in optimizing the process and troubleshooting both process and machine issues.

Read More