Injection Know How

Know the Basics of Machine Evaluation, Part I

Ever wonder how many shots are made each day via injection molding?

Read MoreHow to Make the Transition to Electric Presses

Electric injection machines are becoming more and more prevalent, and as they hit the shop floor, you are responsible for making them produce parts with dimensions, appearance, and performance to client specifications.

Read MoreDon't Neglect Cooling... There's Money to Be Made

For most injection molding jobs, cooling is 95% of the cycle time.

Read MoreBalanced Filling Is Critical for Holding Molding Tolerances

Processors face a multitude of challenges whenever they approach an injection molding machine.

Read MoreGood Reasons to Make a Short Shot, and How to Do It Right

Making a proper short shot is an important aspect of practicing “scientific molding.” Upon startup of almost any mold, the first step is to make a short shot.

Read MoreInjection Molding Know-How: The ABCs of Delta P: Setting the First-Stage Pressure Limit

Here’s another trick of the trade that will make your life easier.

Read MoreInjection Molding Know-How: Drying Tips: A Dozen Details You Should Know

Drying is complicated.

Read MoreToday's Lesson: Drying (Part 1)

Listen up, please: This is going to make your life easier.

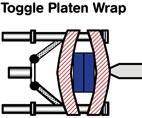

Read MoreHow to Solve Uneven Clamping

Of the hundreds of variables involved in injection molding, clamping mechanisms and platens often get less attention than they deserve.

Read MoreFind the Source of Visual Defects

The appearance of visual defects on parts such as cracking, crazing, grooves, ripples, wave marks, and flaky brittleness often indicates more than an aesthetic problem.

Read More