Injection Know How

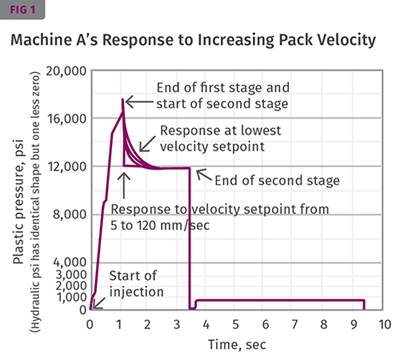

INJECTION MOLDING: How Does Your Machine Control Pack Velocity?

You’ll need to find out in order to develop a molding process that you can repeat from machine to machine and mold to mold.

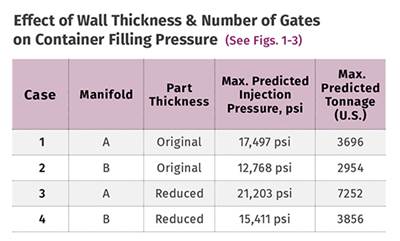

Read MoreINJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

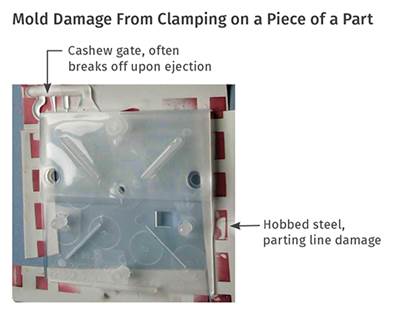

Read MoreINJECTION MOLDING: Setting Mold Protection Takes Time But Saves More

Mold protection is often neglected, but it more than pays for the time and attention required.

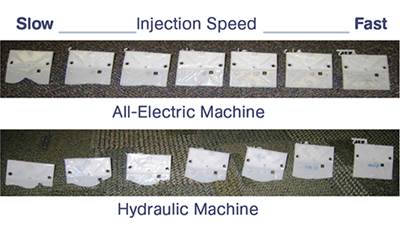

Read MoreINJECTION MOLDING: Troubleshooting Bridging

Bridging is an aggravating problem that can shut you down. Here's how to find it and fix it.

Read MoreINJECTION MOLDING: ‘Know Your Machine’

Many molders think they “know their machine,” but in reality do not. They get consumed by the demands of day-to-day production requirements and lose sight of the big picture.

Read MoreScrew Speed Versus Recovery Time

Many molders don't take screw-rotation speed into account when developing a process for a new mold. Here's why they should.

Read MoreShutting Down & Starting Up An Injection Molding Machine

Whether your press is going down for repairs, a holiday, or a slow production schedule, proper shut-down and start-up procedures must be followed.

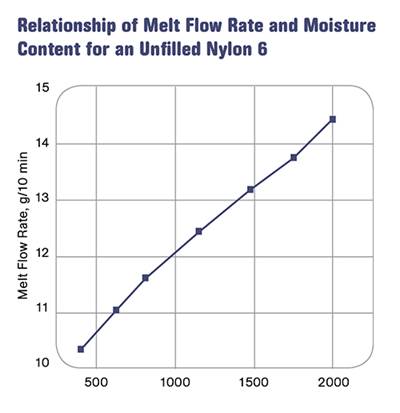

Read MoreMelt Flow Rate Testing–Part 8

Here are the steps to take in cases where the MFR is not provided by the polymer supplier.

Read MoreHow to Establish an Acceptable Range for Pressure at Transfer

Pressure at transfer tells you the viscosity of the resin, providing the fill time is the same. Monitoring pressure at transfer—or better yet, the integral under the pressure vs. time curve—provides insight into the process.

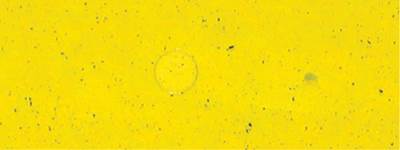

Read MoreMinimizing Black Specks

Black specks in molded parts are one of the most infuriating problems to resolve on the shop floor. Here's how to fix them.

Read More