Melt Flow Rate Testing–Part 8

Here are the steps to take in cases where the MFR is not provided by the polymer supplier.

The number of commercial materials that employ a melt flow rate (MFR) value as part of the published property profile attests to the usefulness of the test. Virtually every grade of material within many polymer families provides this data point, and certifications will almost always list the MFR value for every lot. But there are some polymers where the availability of a MFR value is inconsistent across the base of suppliers, and there are a few polymer families where a MFR value is rarely provided by any supplier.

The reasons for this vary. Some of it is convention. Amorphous PET, for example, does provide a value that is related to molecular weight (MW). But instead of using MFR, the manufacturers of these materials have chosen to use intrinsic viscosity (IV). This test involves creating a dilute solution of the polymer in the appropriate solvent and then comparing the flow rate of this solution to the flow rate of the pure solvent through a piece of glassware of a standardized geometry. The greater the difference between these flow rates, the higher the IV of the material and the higher the average MW of the polymer. Performing the IV test is more complicated because of the need for a delicate apparatus and the use of some very noxious chemicals. However, this test can be conducted practically at room temperature. This removes the need for drying the material as a preparatory step, something that is required when testing in the melt state.

Filled materials are another example where MFR testing is frequently avoided. This seems particularly true of filled and reinforced semi-crystalline resins such as polyesters, nylons, and polyphenylene sulfide (PPS). In PPS, for example, where virtually all molding and extrusion grades of the polymer are highly filled, it is essentially impossible to find a MFR value on the data sheets. The one exception is the unfilled materials that are used either in coatings or as the feedstock for the filled compounds.

The avoidance of the MFR test for the filled materials is related to last month’s column. The presence of the filler decreases the MFR. The value derived from the test is more dependent upon the filler content and type and less upon the MW of the polymer. The presence of the filler can also increase the variability of the test results, making it difficult to arrive at a meaningful specification. However, the avoidance of the MFR test in filled and reinforced materials is far from universal. Many suppliers of glass- and mineral-filled materials, including polypropylenes and polycarbonates, still use the MFR test as a quality-control metric and to provide values for their literature.

PPE/PS alloys represent an interesting example of how conflicted the industry can be over the use of this test. Anyone who worked with GE Plastics (now Sabic Innovative Plastics) in the 1970s and 1980s knows that their Noryl data sheets never used to provide MFR values and instead relied upon capillary rheometer data. If you were to question the technical people at GE about this they would tell you that the MFR test does not tell you anything about PPO materials. But in the 1990s the MFR numbers began to appear on their data sheets and today they are commonly found even for some filled grades. Some other suppliers have followed suit while others do not provide MFR values for their PPE/PS materials.

The polymer where there seems to be a general consensus on avoiding the use of the MFR test is nylon. Regardless of the type of nylon, MFR tests are almost never done and values are rarely provided on the data sheet. If any measure of MW is provided, it usually comes in the form of a value known as relative viscosity. This is a value based on the same type of solvent-based test used for intrinsic viscosity, but the units in which the results are reported are often different.

Nylon presents some special challenges for the MFR test. Because it is a hygroscopic material that can hydrolyze in the melt state, all samples of nylon that are tested in the melt state must be dried before testing. This is also true of materials like polycarbonate and polyester. But nylon creates additional problems because of the way that the moisture that remains after drying influences the flow of the polymer. Most materials that can hydrolyze must be dried to moisture contents of less than 0.020% (200 ppm). The viscosity of many of these materials is influenced by the exact moisture content of the sample being tested.

However, between about 30 ppm and 200 ppm moisture content, the MFR of these materials tends to be essentially constant. But unfilled nylons are considered to be adequately dry once the moisture content is below 0.20% or 2000 ppm. It turns out that across the range from 0-2000 ppm the viscosity of nylon varies significantly. Figure 1 shows the relationship of MFR to moisture content for an unfilled nylon 6. The relationship is nearly linear and it spans the entire range between 400-2000 ppm. Once the moisture content drops below 400 ppm the MFR values begin to decline more rapidly.

Anyone who has ever molded nylon knows this. Very dry nylon has a higher melt viscosity and presents challenges in filling long, thin flow paths. This is the reason that suppliers of nylon advise processors to “leave a little bit of moisture in the material.” Remember that when we perform the MFR test we are often comparing the result for raw material to that of molded parts and we are looking for a certain threshold in the change from pellets to parts to tell us if we have done a good job of preserving the MW of the polymer. But the data in Fig. 1 show that the result obtained from a single sample of material can vary by more than 40% simply as a function of the moisture content of the sample. This makes obtaining a consistent result very difficult and it makes interpretation of a pellet-to-part comparison quite challenging.

There is a way around this. It involves creating a calibration plot such as in Fig. 1. Then when the MFR test is performed, the moisture content of the sample is measured at the same time and the result is then normalized to a particular moisture content such as 0.10% (1000 ppm). Therefore, a MFR of 13.3 g/10 min measured at 1500 ppm would be reported as a normalized value of 12 g/10 min at 1000 ppm. A value of 10.4 g/10 min reported at 400 ppm would also be reported as a normalized result of 12.0 g/10 min at 1000 ppm.

In this case two tests that appeared to produce significantly different results are shown to represent essentially the same values when the effects of moisture content are considered. For most people this is just too much work. The alternative is to perform the solvent-based test. But for those who do not wish to tackle the challenges associated with the solution testing, the much simpler MFR test can still be made to work even with nylons.

In our next installment, we will discuss the meaning of a related property that is beginning to appear on an increasing number of data sheets; the melt volume rate. We will review the relationship of this measurement to the melt flow rate and the reasons for its increasing popularity.

ABOUT THE AUTHOR

Michael Sepe is an independent materials and processing consultant based in Sedona, Ariz. with clients throughout North America, Europe, and Asia. He has more than 35 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting, and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com.

Related Content

Redesigned Laser Scanner Boasts Improved Accuracy, Resolution, Versatility, and Efficiency

Nikon Metrology’s new LC15Dx is ideal for efficient measurement and inspection of manufactured components including intricate plastic parts.

Read MoreTry This Alternate Method for Heating Your Torque Rheometer

Rheometers are generally not on all the time. And most users have found that the first test run in the instrument after heating up is not very reliable and is usually discarded. Try this method instead.

Read MoreUpgraded CT Scanning and Multi-Sensor Coordinate Measuring Machines

Werth’s TomoScope S Plus 240 systems boast more than double the measuring volume as their predecessor with almost the same size.

Read MoreMetaspectral to Advance Vision Technology for Recycling

Company received further funding from British Columbia’s CleanBC Plastics Action Fund

Read MoreRead Next

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreMelt Flow Rate Testing – Part 2

To fully appreciate the strengths and weaknesses of the melt-flow-rate (MFR) test it is important to know something about the way the test is performed.

Read MoreMelt Flow Rate Testing—Part 3

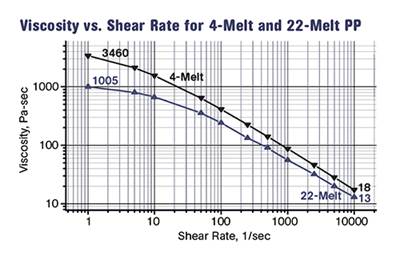

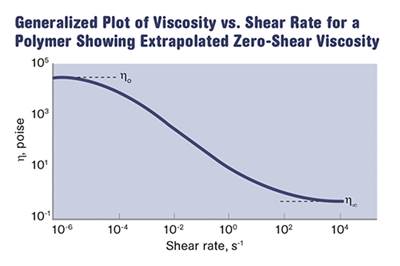

There is a well-established relationship between something called the weight-average molecular weight of a polymer and a parameter known as the zero-shear viscosity.

Read More

.jpg;width=70;height=70;mode=crop)