Injection Know How

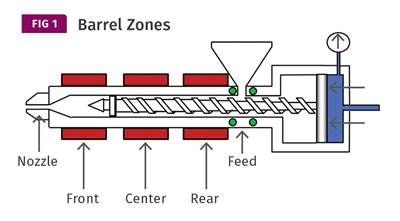

Injection Molding: How to Set Barrel Zone Temps

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

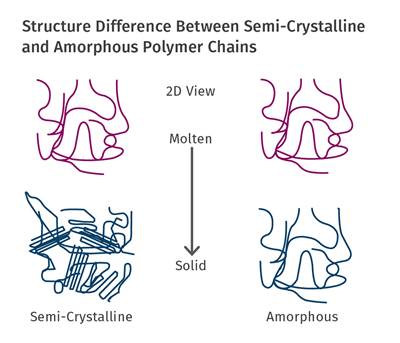

Read MoreInjection Molding: Melting Amorphous vs. Semi-Crystalline Plastics

Understanding the differences in how each melts is crucial to obtaining melt uniformity.

Read MoreInjection Molding: Nozzle Heaters & Thermocouples: A Case of Wiring Done Wrong

Incorrect placement of wires for these components frustrates molders and costs them money to boot.

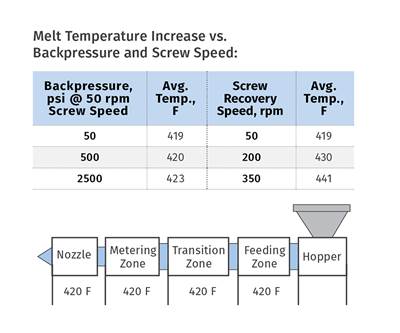

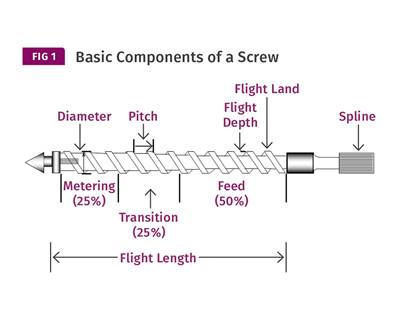

Read MoreInjection Molding: No, Backpressure Does NOT Raise Melt Temperature

It’s a classic confusion between cause and effect. Melt temperature rises when screw speed is increased. Check out this data.

Read MoreInjection Molding: DOEs Done Right

Doing DOEs for the sake of doing them wastes time and money. But they can provide vital information to determine which process variable is determining a critical part characteristic.

Read MoreInjection Molding: Put Out the Production Fire Once and for All

A deliberate approach to failure assessment, root-cause analysis, solution development, and continued monitoring is the only way to get off the treadmill of chasing the latest production problem.

Read MoreInjection Molding: Time for Another Look at Non-Return Valves

First and foremost, they must seal properly, and check valves with stepped angles or radiused seats perform the best.

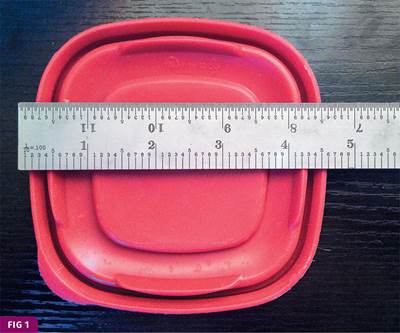

Read MoreInjection Molding: Are You Using More Than 65% Of Your Barrel Capacity?

If you are, you are inviting Murphy—as in trouble—to the party.

Read MoreClamp Tonnage: More Is Better...Right?

Determining the correct tonnage provides a foundation that must be rock-solid to avoid flash and damage. But applying excessive force can create problems with the part, mold, and machine.

Read MoreHow to Duplicate a Process From Press to Press

To adopt the right approach you must distinguish between machine and plastic parameters.

Read More