Injection Know How

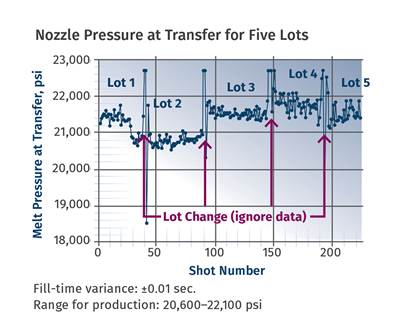

How to Know When Your Process is Ready to Make Acceptable Parts

Focus on six key metrics to help you determine when a process is lined out and stable enough to start production.

Read MoreBack to the (Re)Grind

Some amount of scrap—generated in startup, shutdown or defective parts—is inevitable. How can you reclaim regrind into new profitable parts?

Read MoreUse This Check List to Get Your Machine Properly Installed

Whether you bought a new machine or one that’s been refurbished, you need to prepare for installation so that it can be executed as seamlessly as feasible. Here some advice.

Read MoreFundamentals of Proper Press Shutdown

Press shutdown procedures have a significant impact on achieving smooth machine startups and restarts to improve uptime. Here’s a procedure you might want to deploy in your molding operation.

Read MoreThe Cosmetic Process Window: Key to a No-Tweak, Robust Process

Establishing a process with the widest possible cosmetic window can help put your injection molding on cruise control.

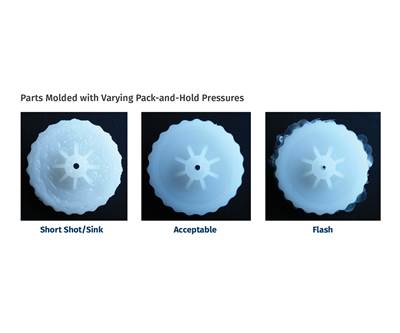

Read MoreDon’t Get Caught in the Flash-and-Shorts Chase

Injection molding’s most common defects can have inverse correlation, where correcting one causes the other, leading to the “chase.”

Read MoreFollow These Tips to Sanitize Machine Controller Screens & Buttons

Keeping your workers safe from the coronavirus makes it extremely important to institute a sanitizing procedure on all touch surfaces of the controller, screen and operating panel. I did some research and here’s what I found.

Read MoreIn Search of a Universal Setup Sheet

Duplicating a process from one injection machine to another is frustrating and time-consuming. Develop a mold-specific setup sheet that works in all kinds of presses by differentiating plastic parameters from machine parameters and duplicating those plastic conditions from machine to machine, electric or hydraulic.

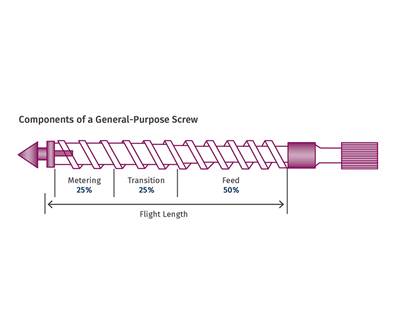

Read MoreRevisiting Shot Size vs. Barrel Capacity

We’ve covered this topic before, but it’s important enough to warrant another look..

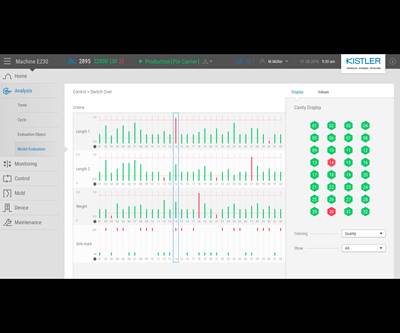

Read MoreHow Can Molders Achieve Effective Process Monitoring?

You have developed a proper process; now you need to monitor that process to ensure its stability through a run.

Read More