Injection Know How

The Importance of Hot Nozzle-Tip Mating Against a Cold Sprue Bushing

Done improperly, the result is a cold slug in the nozzle/sprue and a production stop. But there is a better way.

Read MoreTime to Swap Out Those General-Purpose Injection Nozzle Tips

Still the standard in the industry, GP nozzle tips can cause a myriad of problems for molders. There are alternatives out there that should be examined.

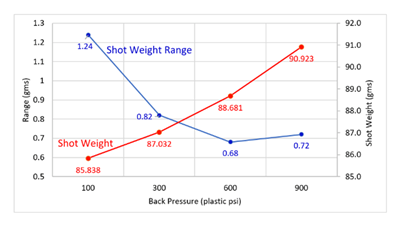

Read MoreHow Backpressure Optimization Affects Melt Preparation

Backpressure is often the least understood of the settings in an injection molding process, even though it can play a significant role in the final quality of the part. Let’s start with understanding what backpressure is and then learn how to optimize it for a given mold.

Read MoreHow Important is Minimizing Residence Time in Injection Molding?

Does a focus on the concept of “minimum residence time” distract attention from areas of injection molding that have more of a direct impact on melt quality?

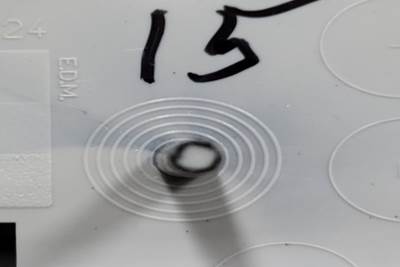

Read MoreUnderstanding Flow Fronts and Defects

Flow-front behavior and corrections are key to solving many common molding problems —what is your process’s flow trying to tell you about your part?

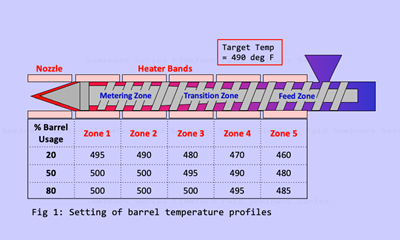

Read MoreMelt Preparation Part 1: Melt Temperature Optimization

A homogenous melt is required for consistent part quality, but achieving it requires balancing a number of factors, including barrel usage and temperature as well as screw speed, backpressure and residence time. Learn how to prepare your melt for molding success in this two-part series.

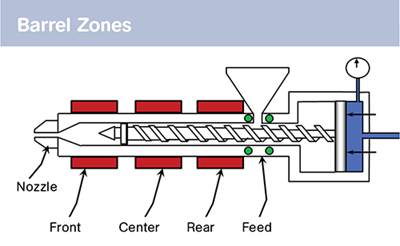

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreWhat is Backpressure and How Should We Calculate It?

Does using an intensification ratio to calculate backpressure result in an accurate reflection of what’s happening in the barrel? Newer machine technologies have us revisiting an old project with fresh eyes.

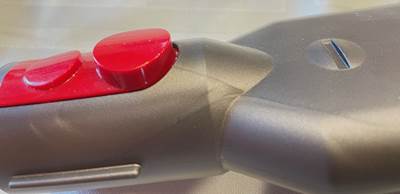

Read MoreWhat to Do About Weak Weld Lines

Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate.

Read MoreAre Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

Read More