Injection Know How

Checking and Controlling Nozzle Body Temperature

Temperature control is critical from feedthroat to nozzle tip. Yet despite advances in machinery, this continues to be an issue for molders. Here’s what to do about it.

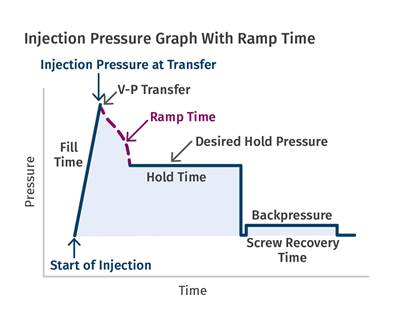

Read MoreV-to-P Ramp Time and Over-Travel

Many injection machines use ramp time to control the transition from injection pressure to hold pressure and reduce over-travel. Do you know how to set yours?

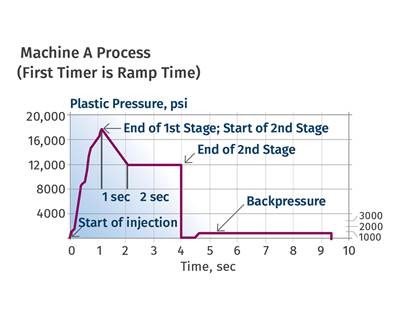

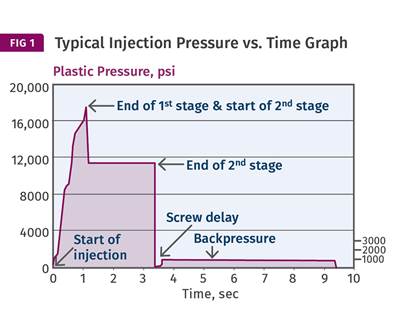

Read MoreGraphing Injection Pressure: What Should Pack & Hold Curves Show?

Are you sure your press is doing what you want? Visit your controller often to ensure your machines plot the pressure vs. time graph for all your processes. Here let’s focus on pack and hold.

Read MoreUnderstanding—and Using—Decompression to Your Advantage

Decompression—aka suckback—is a very important setting on an injection molding machine. On today’s machines, molders typically get the option to set decompression before and after screw rotation/recovery. Are they using this feature to their advantage?

Read MoreHow to Deal With Residual Stress in Molded Parts

Here are design, molding, and fixturing considerations to help you handle this unavoidable issue.

Read MoreHow to Manage Pressure Loss in Injection Molding

Achieving a process window wide enough to ensure consistent part quality depends on achieving sufficient pressure at end of fill.

Read MoreHow to Quickly Verify Your Machine & Process Setpoints

For a quick check of your process setup, the injection-pressure-vs.-time graph is your best tool.

Read MoreThe 'Butterfly Effect' in Injection Molding—A Connected Process

In injection molding, a seemingly minor change in a setpoint can have a significant impact on part quality and process robustness and repeatability. That’s why Scientific Molding focuses on process outputs, not setpoints.

Read MoreMold-Clamping Details for Profit

Taking time to sweat the details of clamping is not much fun, but they do make a difference in a company’s bottom line.

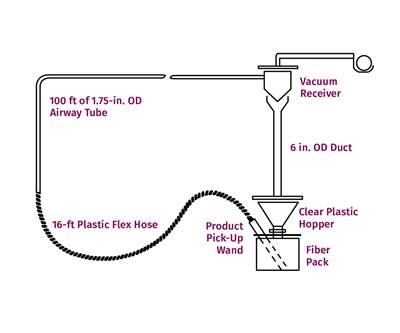

Read MoreWhat’s With All the Static?

Static buildup on polymers can cause a variety of problems, some rather unpleasant. Yet there’s an inexpensive way to eliminate it, and we have data as proof.

Read More