Injection Know How

PART 2: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. In part one we covered the why. Here’s the how.

Read MorePart 1: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. Here’s why.

Read MoreIdentifying and Correcting Splay

Splay adjustments can be a simple fix, or can require several hours of babysitting a press and head scratching. Learn to find the root cause.

Read MoreInjection Molding: Sliding vs. Locking Ring—Which Non-Return Valve Is Right for You?

The locking-ring style appears to dominate the market, as most believe it makes a make a better seal and leaks less. But is this really so?

Read MoreInjection Molding: Is There a ‘Most-Important’ Process Parameter?

A case can be made for multiple variables—fill balance, fill time, injection pressure, cavity pressure—as most important. But there is something else altogether that is essential to successful injection molding.

Read MoreInjection Molding: Fill Based on Volume, Not Weight

Most parts should be 90-99% full after first-stage—by volume not weight. Here’s why that’s important and how to make a first-stage-only part.

Read MoreInjection Molding: Safety First—Know the Compatibility of Different Resins

Certain materials don’t play well together when mixed. So it’s best not to. Here are some guidelines.

Read MoreInjection Molding: Process Documentation Is Crucial to Making ‘Identical’ Parts

Use a machine/mold setup sheet to document plastic parameters and use them on any acceptable machine into which the mold is placed.

Read MoreInjection Molding: A Practical Approach to Calculating Residence Time

Toss the formulas. The best way to determine residence time is to conduct a simple experiment.

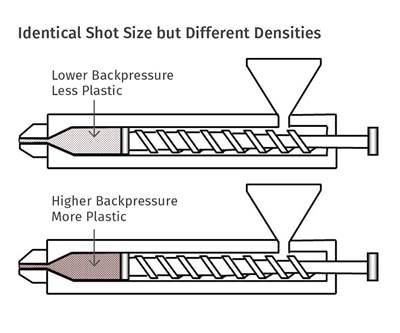

Read MoreInjection Molding: How Backpressure Adjustments Influence Shot Size

Raising backpressure results in increasing shot size, which can cause a host of other problems.

Read More