Injection Know How

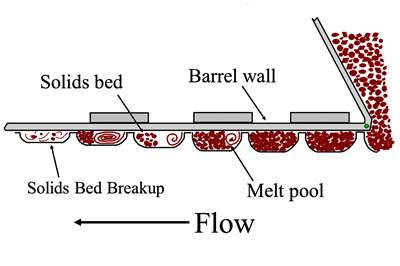

Improve Quality & Productivity With Advanced Screw Design

Most molders are still running with screw designs that haven’t changed much in 30 years. But they don’t need to.

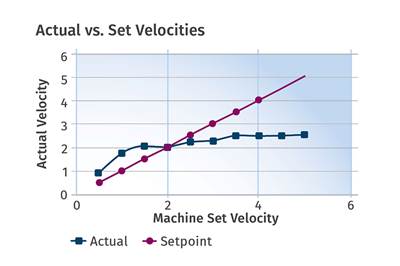

Read MoreStop Controlling Your Injection Molding Process with Machine-Only Settings

Monitor and record process outputs instead of the machine setpoints to ensure a validated process regardless of any machine deterioration, viscosity changes or other alterations.

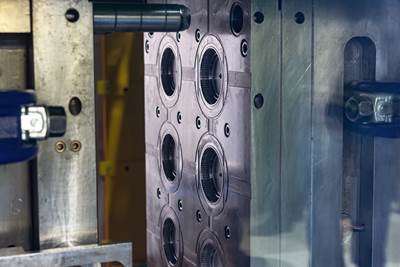

Read MoreHow to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

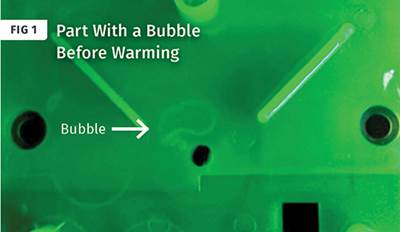

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

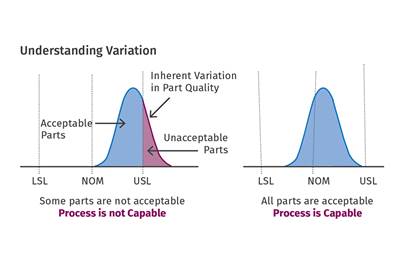

Read MoreCreating a Capable Process Using Process Capability

Know your Cp from your Cpk and how parts can meet dimensional specifications but still not be “capable.”

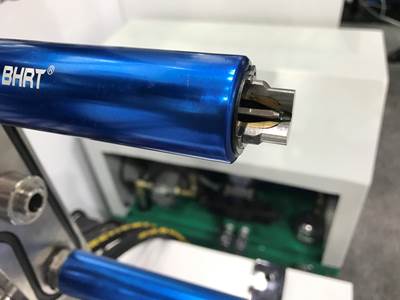

Read MoreMolders’ Block: Dealing With Foreign Materials in a Hot-Runner System

Understanding plastic flow can help you understand how foreign materials move—or don’t move—through your hot-runner system.

Read MoreHow to Set Up Mold Protect on Your Injection Machine

Set the start position for mold protect where anything in the mold could be subject to damage.

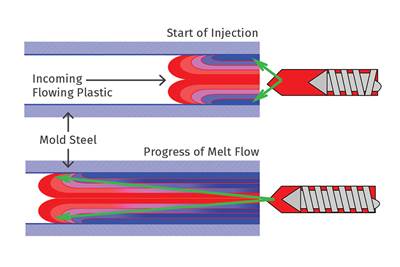

Read MoreUnderstanding Fountain Flow in Injection Molding

The phenomenon of fountain flow affects almost every aspect of the molded product—starting with filling, extending to pack and hold, and ultimately manifesting in part defects like bubbles and voids.

Read More