Injection Know How

Pay Attention to Your Nozzle Body & Tip

These are overlooked components that can cost you thousands.

Read MoreInjection Molding: How to Set Second-Stage (Pack & Hold) Pressure

Most molders work with two parameters for establishing second-stage pressure. But within Scientific Molding there are actually four.

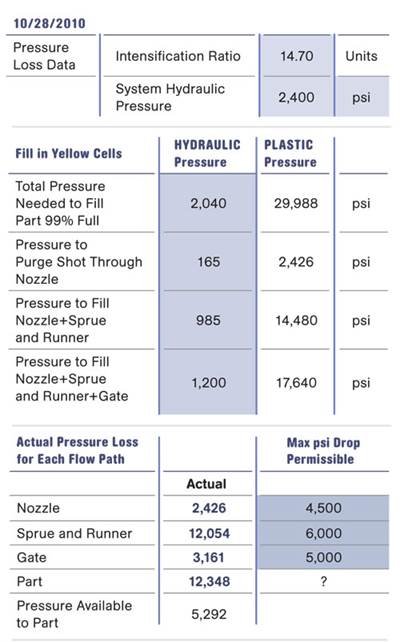

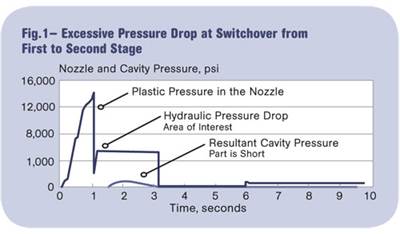

Read MoreInjection Molding: Understanding Pressure Loss In Injection Molding

One of the more prominent trends in processing is the need for higher plastic pressures to mold parts.

Read MoreInjection Molding: Processors: Teach Part Designers The Golden Rule

Make sure the designers you work with understand that there are limits to what processing can do.

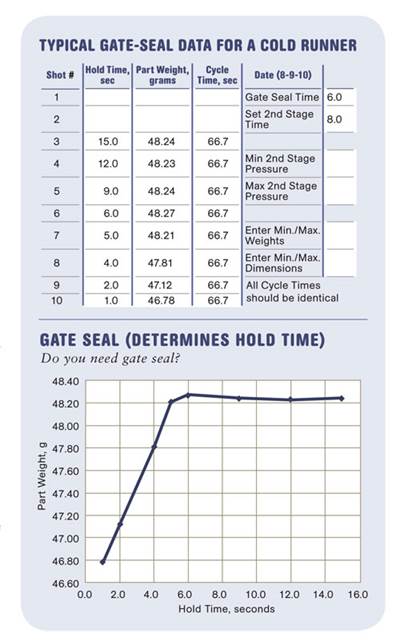

Read MoreInjection Molding: Why & How to Do Gate-Seal Experiments

Part of optimizing any molding process is determining the second-stage injection, or pack and hold, parameters.

Read MoreInjection Molding: Answers to Bozzelli's Drying Quiz

Three questions about drying plastics that everyone should know how to answer.

Read MoreInjection Molding: You Must Dry Hygroscopic Resins

The reason you dry certain plastics is to get the moisture out. But why does the moisture have to be taken out before processing?

Read MoreInjection Molding: Time Now for a Safety Review

For months many of us have been consumed with the Gulf oil pipeline blowout.

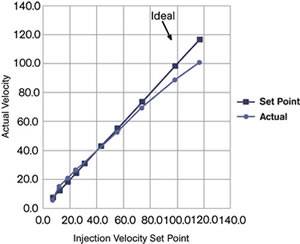

Read MoreInjection Molding: The Basics of Machine Evaluation, Part III

In the last two issues, we started defining some basic tests to ensure your injection molding machine is working properly.

Read MoreThe Basics of Machine Evaluation, Part II

Last month we started defining some basic tests to ensure your injection molding machine is working properly.

Read More