PET Processing

PBT & PET Polyester: Part 2 The Performance Factor

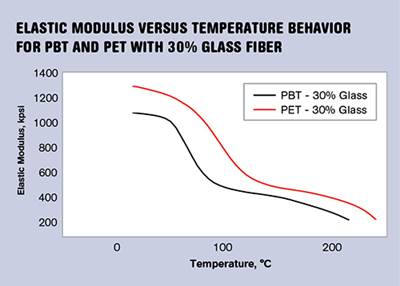

All things being equal, PET will outperform PBT mechanically and thermally. But the processor must dry the material properly and must understand the importance of mold temperature in achieving a degree of crystallinity that allows the natural advantages of the polymer to be realized.

Read MoreNPE: New Machines Exhibit Sophisticated Molding Demos

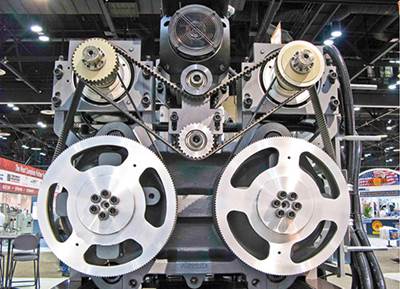

More speed, more power, more precision, and more automated functions accomplished in and out of the mold. That’s exactly what injection machinery suppliers were offering at NPE2012.

Read MoreNow You Can Measure Pellet Moisture In the Hopper, in Real Time

Take the guesswork out of drying with new technology.

Read MoreFoamed PET Bottles for Beer

Now the foam isn’t just on top of the beer, it’s all around it.

Read MoreINJECTION MOLDING: Automation and Integration At K Show

There were new presses of all stripes aplenty at K 2010, but the “wow” factor was supplied by automated work cells and integrated manu-facturing systems performing multiple operations before, during, and after molding.

Read MoreDryers Use Less Energy to Dry PET

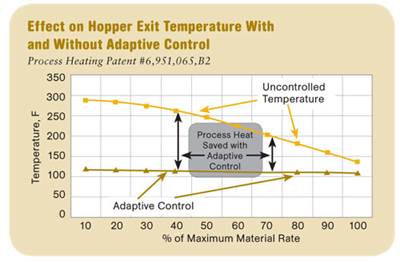

Novatec Inc., Baltimore (novatec.com), is introducing two patented dryer control technologies intended to cut energy costs for processors of PET.

Read MoreNPE News Wrap-up: Resin Dryers

At least 16 companies introduced new dryers at the big show in Chicago. The new models span a range of drying technologies, but most sport features that save space and cost and make the dryers simpler and more reliable.

Read MoreInjection Molding at NPE 2003

Show goers will see an electric injection machine in nearly every press maker’s booth this year, and electric/hydraulic hybrids in several.

Read MoreNew Approach to PET Drying To Debut This Fall at K 2010 Show

An Italian maker of auxiliary equipment has come up with a new system that combines several unusual concepts to make high-volume PET drying faster and more consistent with lower energy use.

Read More