Injection Molding

Lab System Targets Large Part, Process Development for Combo Injection Molding, PUR Coating

KraussMaffei has paired an MXW 4500 injection molding machine featuring more than 5,000 tons of clamp force with two RimStar polyurethane (PUR) metering systems and three different mixing heads in a new ColorForm lab line at its facility in Parsdorf, Germany.

Read MoreSodick-Plustech Promotes Shinohara

Kohei Shinohara has been promoted to senior vice president of Plustech, the North American subsidiary of Japan’s Sodick injection molding machines.

Read MoreStandalone Servo-Driven Sprue Picker

Wittmann recently introduced a standalone version of its WX90 sprue removal robot capable of working with virtually any brand of injection molding machine.

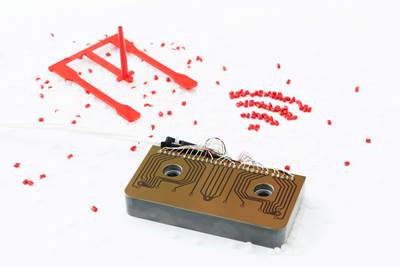

Read MoreThin-Film Sensors Integrated Directly Onto Cavity Surface

Fraunhofer IST researchers say the wear-resistant thin-film sensors are deposited onto the tool surface, enabling direct temperature and flow measurements in critical areas of a mold.

Read MoreUse Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the business and conclude that this is a key area that cannot be overlooked.

Read MoreEngel Installs Massive Injection Molding Machine for Trials, Testing

The Austrian company’s large-machine plant in St. Valentin now has a duo 5500 combi M press, with nearly 6,200 tons of clamp force and shot weights up to 93 lbs, available for customer trials.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreNovel Injection Unit’s Commercial Debut

NPE2024: Md Plastics is now offering for sale injection machines incorporating its novel Inject-EX injection-unit design with an inline screw and plunger.

Read MoreRevisiting the '5 M's' of Molding

All injection molding ultimately comes down to the “Man, Mold, Machine, Material and Method.” But those key aspects can be viewed differently if you’re auditing mold changes before startup or troubleshooting changes for an already validated process.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read More