Mold Simulation

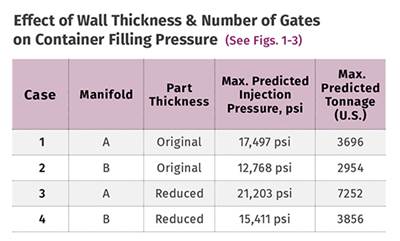

INJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

Read MoreFEA Software Predicts Material Response to Repeated Snap Fits

Improved finite-element modeling accounts for viscoelastic response to multiple stress-strain cycles.

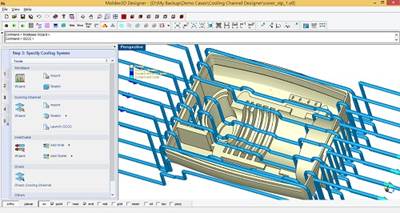

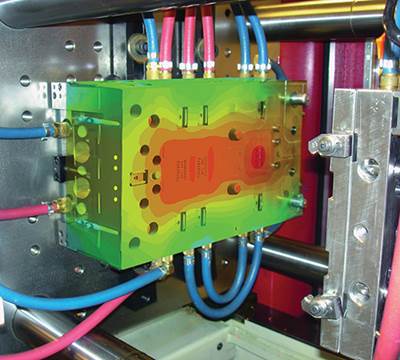

Read MoreTOOLING: Mold Simulation Software Gains Speed & New Functionality

Enhancements in simulating conformal cooling, hot runners, MuCell foaming, shrink/warp, and fiber reinforcements.

Read MoreVero Software Has New Owner

Hexagon of Sweden adds Vero to its Intergraph and CADWorx brands.

Read MoreProcess Technologies for TP Composites in Automotive

In one session, learn about process simulation, rapid heat-cool molding, and continuous prepreg tape laying and rapid consolidation.

Read MoreCould your RFQ process be jeopardized by a retirement?

The moldmaking industry has lately lamented its talent depletion by demographic shift, as aging toolmakers step away from their benches for the last time, primarily focusing on the shopfloor and steel-cutting implications, but what about the front office and quoting?

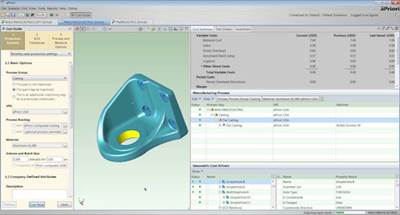

Read MoreSOFTWARE: More accurate quotes, faster

Cost-estimating software is taking mold quoting from back-of-the-envelope guesswork to computer-generated model.

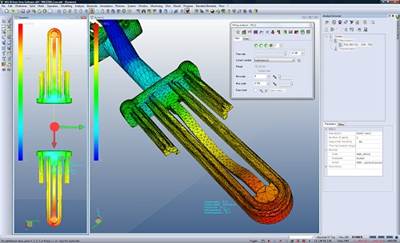

WatchNews in Molding Simulation at K 2013 Show

At October's K 2013, suppliers of injection molding simulation software displayed solutions addressing a number of hot topics, as well as technology to speed up handling of larger models and multiple iterations.

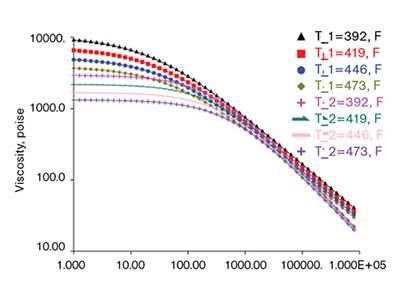

Read MoreMold Simulation: Get Best Results With Good Materials Data

Want the best results from your flow analysis software? Of course you do. But you stand a better chance for success if you pay particular attention to the material data used by the software.

Read More