Mold Simulation

Virtual Tool Alloy Selection Confirms Benefits in Cost & Part Quality

Using simulation to understand cost-benefit ratio in using tool alloys with high thermal conductivity.

Read MoreSeeking Moldmakers That Are Fast…and Smart

Now in its 15th year, MoldMaking Technology’s Leadtime Leader Award is once again seeking out tool shops that get things done.

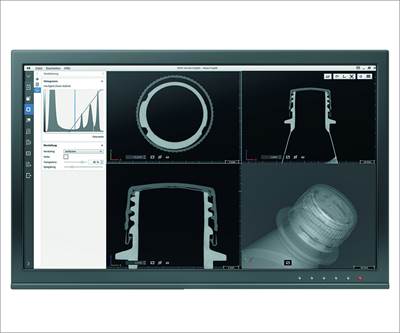

WatchHow CT Scanning Can Cut Your Product-Development Time

Computed tomography scanning offers molders a wide range of benefits, often saving them hundreds of hours during the processes of mold building, mold tryout, and first- article approval. Here’s what you need to know.

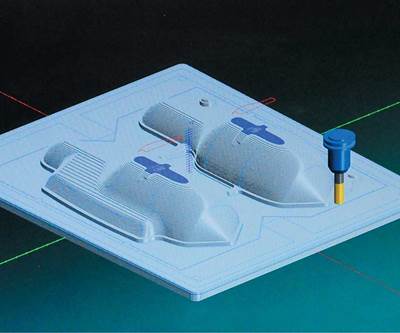

Read MoreCAM Adds Agility to Custom Thermoformer

CNC machining permeates ATI’s business, making its operations more efficient and responsive.

Read MoreRJG Introduces Low-Cost Part Design Analysis

New service provides quick and affordable analysis early in the design phase.

Read MoreUse Molding Simulation To Avoid Surface-Finish Defects

It’s not just for successful mold filling and cooling. Simulation can help predict and overcome cosmetic defects in molded parts.

Read MoreBeaumont Tech Buys Material Characterization Business from Autodesk Moldflow

A trainer in mold analysis and supplier of simulation services acquires testing facilities used to obtain materials data needed for accurate simulation.

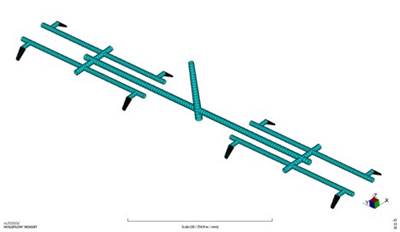

Read MoreMelt Delivery Systems: Going Against Tradition

When it comes to part design, the importance of a properly designed melt delivery system is often neglected.

Read MoreMoldmaker Branches Out With New Services & Technologies

NyproMold offers new development tooling program and the latest in servo drives, enhanced cooling, and CT scanning.

Read MoreThe Five “Ms” of Molding—Part II: The Mold

A bad mold can cripple a process; learn what areas should be considered as a tool is evaluated and reviewed.

Read More