Pipe, Profile & Tubing Extrusion

Switch to AC Drives & Save Energy, Maintenance Costs

Smaller, cooler AC packages can be retrofitted to existing lines to slash energy use and maintenance costs.

Read MoreEXTRUSION: Why Barrier Screws & Rigid PVC Don’t Always Mix

RPVC’s somewhat unusual melting mechanism makes it unsuited to traditional barrier type designs.

Read MoreTeel Plastics: Where Science, Tech, Quality and Innovation Meet

This family-owned custom profile and tubing business controls its own destiny by controlling, well, everything.

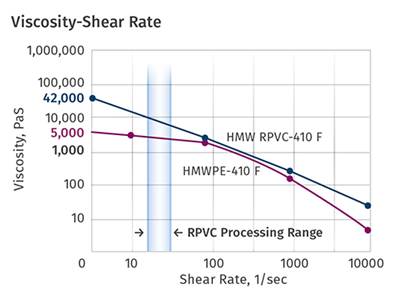

Read MoreEXTRUSION: Processing Rigid PVC? Know Your Rheology

Before choosing and sizing extruders for running rigid vinyl, it is wise to bone up on the viscosity behavior of the material.

Read MoreCheck Out the New Purging Compounds Knowledge Center

Get expert advice on how to solve black specks, color streaks and other quality problems.

Read MorePlastics Technology's Drying Supplement

Learn from the experts, including savvy processors, on how to get drying done right.

Read MoreGranulate or Shred: Which Makes Sense for You?

That is the size-reduction question confronting many processors today. Look here for some guidance.

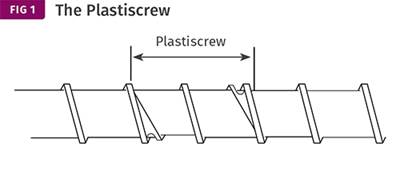

Read MoreEXTRUSION: Effect of the Screw Flight On Melt Temperature, Energy Use

So-called rules of thumb regarding the design of flight clearance and width do not consider the temperature effect, both from the point of view of melt temperature and energy efficiency.

Read MorePlasticComp Extrudes LFT Pipes & Profiles

The system uses crosshead profile dies to coextrude fiber tows and unidirectional tapes as continuous axial reinforcement in the extruded profile.

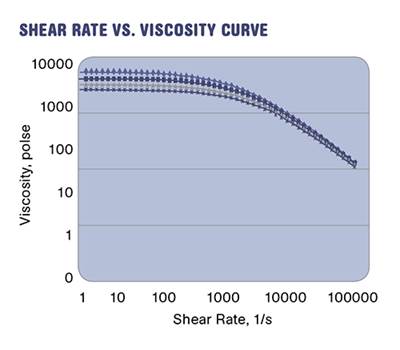

Read MoreTelltale Temperatures

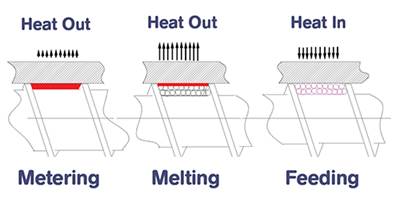

Here's how to get a 'feel' for a screw design without actually seeing it. And how to use this information.

Read More