Processes

Blow Molding News at K 2013

All-electric machines of all types were the stars of the show, but there were a number of other noteworthy developments.

Read MoreMolder Puts the ‘Art’ into Decorating

Custom molder took its expertise in in-mold coloring, IML, and IMD to the next level with the launch of a new division, Artistry of Plastics. The operation utilizes a proprietary technique, trade named Fabric Fusion, which merges resins with textiles to create a unique seamless product design.

Read MoreK 2013: More Efficient, Flexible & User-Friendly Auxiliaries

It’s hard to generalize about auxiliary equipment, but a few trends stood out at K, including: greater energy efficiency, ease of maintenance and cleaning, controls that provide more real-time and historical process information and greater ease of use.

Read MoreHeadlines from the K 2013 Show

Here’s just a taste of the innovations on display, a selection of the top headlines not covered in our September show preview.

Read MoreDecorating at K 2013

WEB EXCLUSIVE: Kurz debuts two systems, including a patented finishing process that decorates 3D geometries.

Read MoreNews in Medical Tubing & Materials

Two innovations in medical tubing and more than a dozen new materials, coatings, and adhesives were on display at June’s Medical Design & Manufacturing (MD&M) East show in Philadelphia.

Read More‘Value-Added’ Molder Adds 3D Printing

Wisconsin molder's recent decision to bring water-transfer printing in-house makes it one of the few processors to offer this decorating technology as part of its full-service offering.

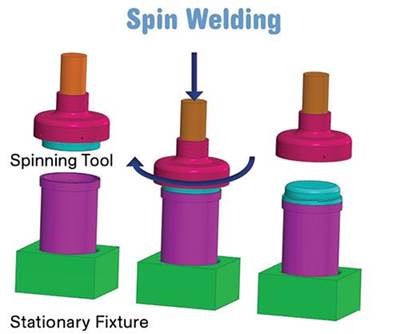

Read MoreHow to Select a Plastics Assembly Process

To make the proper choice, each application must be considered on its own. Each has its own particular characteristics and requirements.

Read MoreNovel Materials Stretch Process Capabilities

The potential for new or unusual materials to broaden the application potential of standard plastics processes was explored in a number of papers at April’s SPE ANTEC conference in Orlando, Fla.

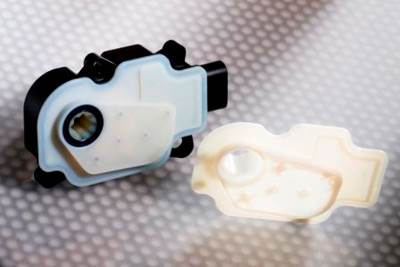

Read MoreLaser-Transparent PBT in Novel Air-Flap Control Unit

WEB EXCLUSIVE: A 20% glass-reinforced grade of Ultradur LUX laser-transparent PBT resin from BASF is being used for the housing cover of a novel air-flap control actuator developed jointly by Germany’s Tier 1 supplier Rochling Automotive and motor developer Precision Motors Duetche Minebea.

Read More