Processes

Plastipak Wins Award for Direct Object Printing Technology

The patented DOP technology for packaging decoration facilitates rapid label changes & saves on logistical costs associated with physical labels.

Read MoreWhat Is the Right Plastics Joining Process for You: Part 2—Available Technologies

The four primary joining technologies—vibration, clean vibration, infrared, hot-gas/convection—offer different benefits and challenges for different applications.

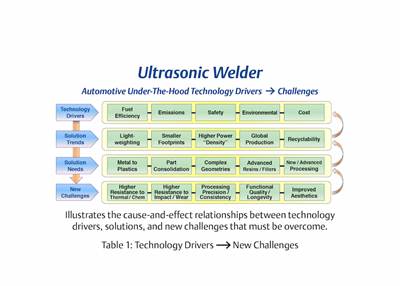

Read MoreWhat Is the Right Plastics Joining Process for You? Part 1

Changing demands, advancing technology and a process-neutral approach to plastics joining for under-the-hood automotive parts.

Read MoreHow to Solve Common Ultrasonic Welding Problems

Understand and address the likely origins of welding problems to keep production on track.

Read MoreNew Hard-Coating Technology for Large, Curved Auto Glazing

New plasma CVD coating over a wet coating offers wider design freedom than previous hard coats.

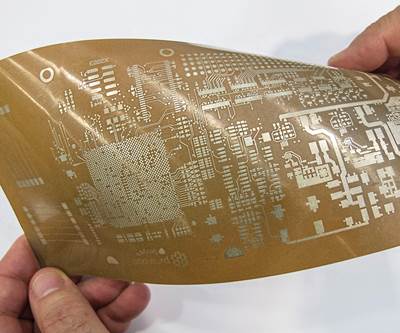

Read MoreDramatic New Potential for Circuitry Printed on Plastics

Novel nano-silver and nano-copper inks reduce costs and complexity, while opening up new applications.

Read MoreRubbery, Velvety, Silky: Properties of Coated Auto Plastic Parts

HapticMapping is an objective approach for determining the haptic properties of PUR-coated plastics.

Read MoreTampoprint Shined at K 2016

With its 60 years of experience in machine engineering, Tampoprint belongs among the innovators of the pad-printing industry, according to founder and chairman Wilfried Philipp.

Read MoreNew Cure for the Headaches of In-Mold Labeling/Decorating

New IML/IMD method combines the best aspects of precut label stacks and labels on a roll with none of their drawbacks.

Read MoreTwo-Stage Injection Meets Molder’s Need for High Precision

Fixed screw and plunger with no check ring hold tolerances of millionths of an inch.

Read More