processing tips

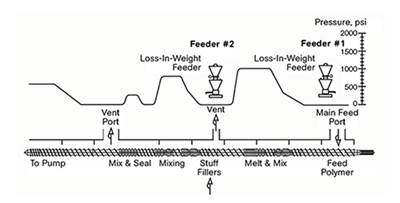

Look Before You Leap: When Direct Extrusion Makes Sense

The process offers great opportunities to extrude a better product at less cost, but it’s not for everyone. The formulation, product mix, and anticipated volumes must be carefully assessed to determine whether DE is the preferred manufacturing methodology.

Read MoreEight Steps Toward a Seamless Mold Transfer

It’s big news when an OEM decides to move a substantial number of molds from one processing operation (either their own in-house/captive facility or an outsourced molder) to another.

Read MoreScrews and Pellets: One Size Does Not Fit All

Screw design, pellet type/size and material behavior are all critical issues to consider to deliver uniform melt to the mold.

Read MoreLook Upstream to Avoid ‘GIGO’ Pitfalls in Extrusion

You may think you have a feeding issue when in reality your problem may be upstream.

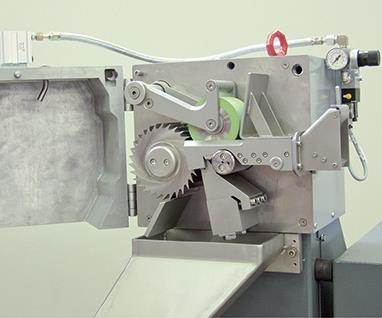

Read MoreFollow These Tips to Select the Right Pelletizer

Start by assessing the status quo, as well as defining future needs. Develop a five-year projection of materials and required capacities. Short-term solutions very often prove to be more expensive and less satisfactory after a period of time. Most of all, know your options.

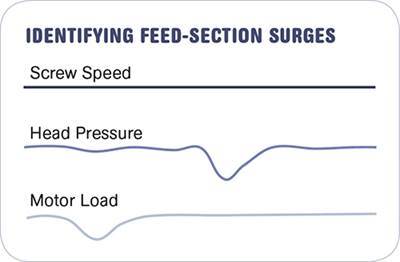

Read MoreOverfeeding Can Cause Surges, Too

Surging can be caused by feed restrictions, as covered in another column, and also by over-feeding or under-melting, discussed here.

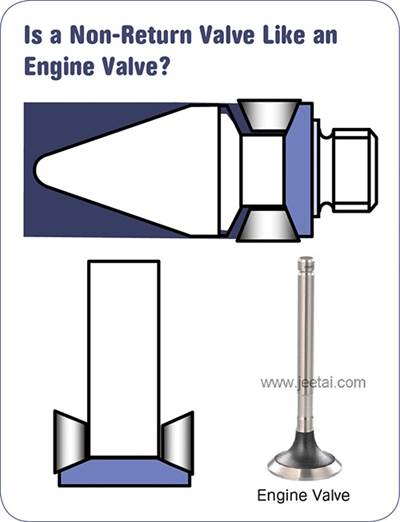

Read MoreWhy Non-Return Valves Leak

We all recognize that the non-return valve is a problem. The question is where is the research to figure out how to correct this so we have a better shot at making more consistent parts

Read MoreSolving Feed-Related Surging

Understanding the causes of surging can help troubleshoot and correct it.

Read MoreWhat to Look for in a Modular, Reconfigurable Conveyor System

As conveyors have become a necessity on the plant floor, conveyor manufacturers have attempted to respond to end-users’ needs for flexibility by creating truly modular, reconfigurable systems.

Read More