processing tips

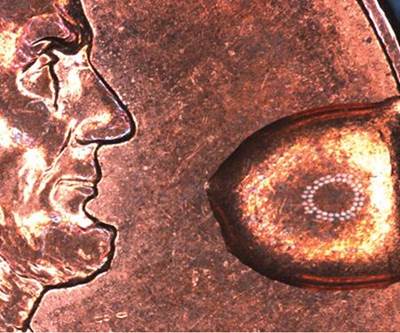

Don’t Overlook Gate Location

Molders take heed: Gate location is the root cause of many molding difficulties. You’ll be doing yourself a big favor by spending some time and thought in determining the best gate location. Here’s what to look for.

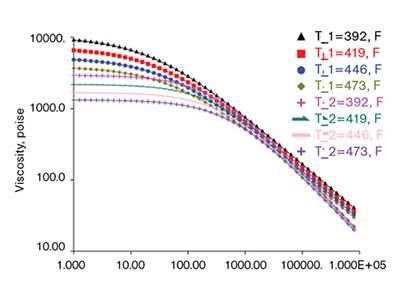

Read MoreMold Simulation: Get Best Results With Good Materials Data

Want the best results from your flow analysis software? Of course you do. But you stand a better chance for success if you pay particular attention to the material data used by the software.

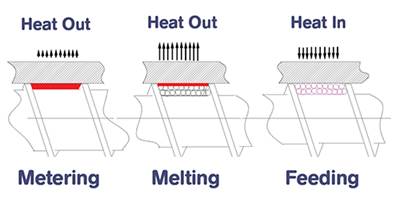

Read MoreTelltale Temperatures

Here's how to get a 'feel' for a screw design without actually seeing it. And how to use this information.

Read MoreHow to Establish an Acceptable Range for Pressure at Transfer

Pressure at transfer tells you the viscosity of the resin, providing the fill time is the same. Monitoring pressure at transfer—or better yet, the integral under the pressure vs. time curve—provides insight into the process.

Read MoreMelt Flow Rate Testing—Part 6

Once degradation has been established, the discussion inevitably turns to how it happened. It might be expected that the answer to this question is widely known. Not so. The good news is that the influences that cause polymer degradation during processing are few.

Read MoreA Processor’s Advice on How to Get Moisture Testing Right

Follow these four steps to ensure your results are on target.

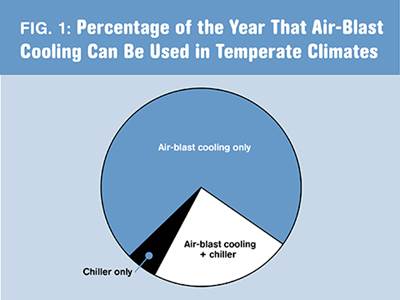

Read MoreOptimize Cooling Water Supply To Reduce Costs

In the last three articles (March, May, Sept. 2012), we introduced the problem of wasted energy in cooling-water systems and presented two types of solutions—minimizing “parasitic” heat gains and raising water temperatures to minimize demand.

Read MoreOptimize Resin Management in Extrusion Blow Molding

In the EBM process, profits depend greatly on how judiciously you use resin.

Read MoreWhich Winder’s for You?

It's time to apply more science to the process of selecting the right kind of winder for your operation.

Read MoreWhy I Still Like Analog Meters

They may not look as slick as their digital cousins, but I find them more helpful in identifying and troubleshooting extrusion problems.

Read More