processing tips

INJECTION MOLDING: How to Tell If Your Non-Return Valve Is Leaking

Check valves are potentially troublesome devices. Here’s how to find out if yours is behaving properly.

Read MoreThe Mystery of Physical Aging, Part 1: Knowing the Difference

In polymers, aging is commonly considered essentially synonymous with oxidation. But there are important differences between this type of chemical aging and less commonly recognized physical aging. Let’s unlock the mystery.

Read MorePrevent & Minimize Downtime in Hot Runner Molding

There are simple explanations for the most common hot-runner problems and equally simple ways to prevent them. One is to take advantage of features often overlooked in today’s hot-runner controls.

Read MoreThe Paradox of Proportioning

Continuous proportioning typically involves a group of gravimetric feeders operating under some form of higher level coordinating control. One would think the result should be a perfectly formulated composite stream. But the devil is in the details.

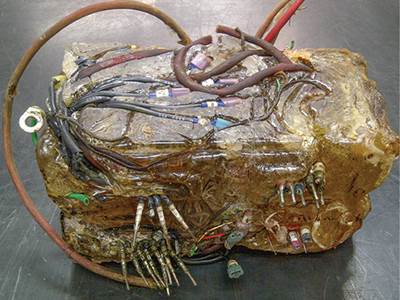

Read MoreAutomation Eliminates Contamination

Many molders use robots to boost output and repeatability, but SSI also uses them to prevent contamination of critical diagnostic products.

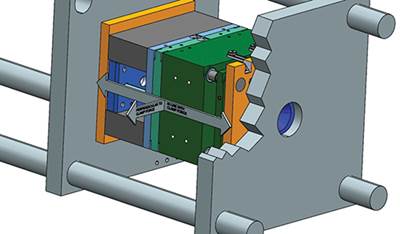

Read MoreTOOLING: Flash-Free Molding: Part 1

A robust process window relies a lot on tooling. So it stands to reason that making a tool change to address issues provides a more robust solution

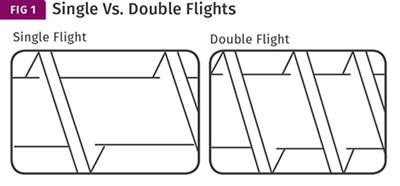

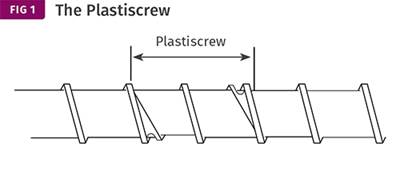

Read MoreEXTRUSION: Double Flights Are Not a Cure-All

There are certain applications where double-flighted feed sections make sense, and others where they don’t.

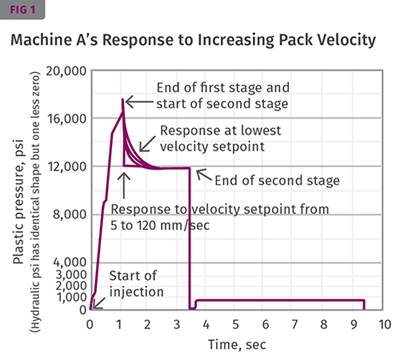

Read MoreINJECTION MOLDING: How Does Your Machine Control Pack Velocity?

You’ll need to find out in order to develop a molding process that you can repeat from machine to machine and mold to mold.

Read MoreEXTRUSION: Why Barrier Screws & Rigid PVC Don’t Always Mix

RPVC’s somewhat unusual melting mechanism makes it unsuited to traditional barrier type designs.

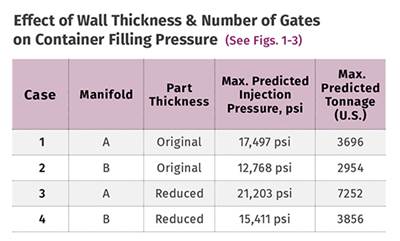

Read MoreINJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

Read More