processing tips

How to Dry PET for Container Applications

PET is extremely hygroscopic, highly moisture sensitive, and one of the toughest challenges to dry. Here are the basic principles of doing it right for rigid packaging applications

Read MoreWhy Processors Are Rediscovering Liquid Colorants

In extrusion, injection, and blow molding, liquid color is enjoying something of a renaissance. Cost is one reason, but advances in pigments, carriers, delivery systems, and innovative service programs have played a role too.

Read MoreThe Importance of Gate Geometry

Gate size and shape—unlike gate location—don’t often get the attention they deserve. Many common assumptions about gate geometry deserve to be challenged

Read MoreHow to Address Uneven Wall Thickness in Stretch-Blow Molding

Many conditions must be met to get the best wall distribution in a PET bottle. Skilled operators are, as always, indispensable.

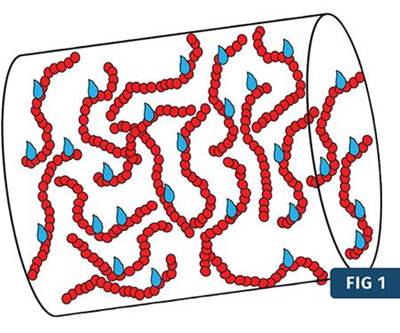

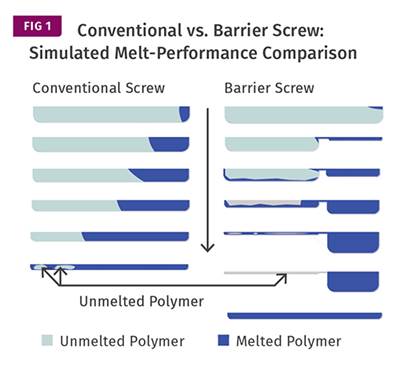

Read MoreUnderstanding Solids-Bed Breakup in Barrier Screws

Barrier screws all but eliminate problems associated with solids-bed breakup. But if they do occur, tremendous pressures can develop, causing screw wear.

Read MoreHigh-Pressure Water: A New Concept for Screw Cleaning

Everyone in a molding plant is on the same page for screw cleaning: Avoid pulling it until there is no alternative. Here are ways for dealing with the inevitable, including an altogether new technique.

Read MoreThe Mystery of Physical Aging, Part 2: Slow Down Aging

Dimensional and property changes depend on the size of the part, molecular weight of the resin, and processing conditions.

Read MoreYour Options for Mold Venting

When should you use machined vents or porous, sintered metals? Here are some guidelines.

Read MoreOptimizing Thin-Gauge Sheet for In-Line Thermoforming

Processing thin-gauge sheet for in-line thermoforming poses unique challenges. Here’s how to cope with them.

Read MoreTOOLING: Flash-Free Molding: Part Two

Parting-line maintenance, mold spotting, and machine conditions can all contribute to flash.

Read More