processing tips

How to Keep Moisture Away From Your APET Sheet Line

Moisture in PET will result in degradation that will foul up sheet and thermoformed products. Keep it at bay by following these tips when drying APET virgin and flake material.

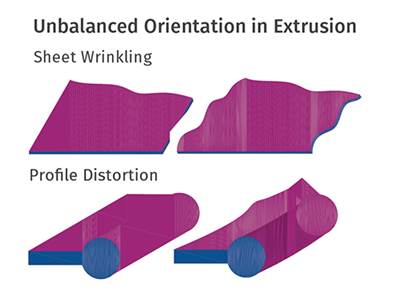

Read MoreExtrusion: How to Adjust for Polymer Shrinkage and Orientation

Polymers shrink and orient. Sometimes orientation is unbalanced, resulting in misshaped parts. But there are steps beyond tweaking the die that can mitigate these effects.

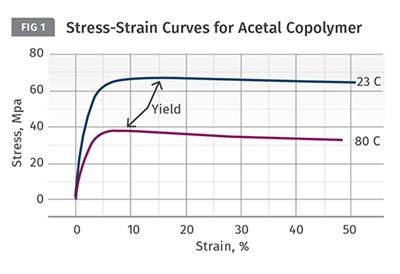

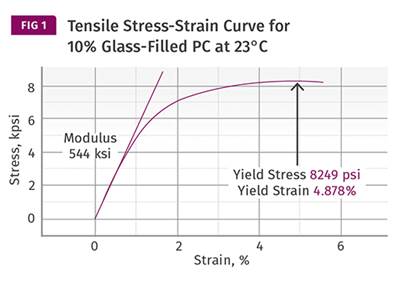

Read MoreMATERIALS: The Problems With Single-Point Data

Polymer properties are not constant as a function of temperature, and even small temperature changes can affect properties.

Read MoreFrom Extruder to Pelletizer: What Happens in Between Influences Quality

There’s a lot more to strand pelletizing than dunking material in water and hoping for the best. Here’s some advice on taking out some of the guesswork.

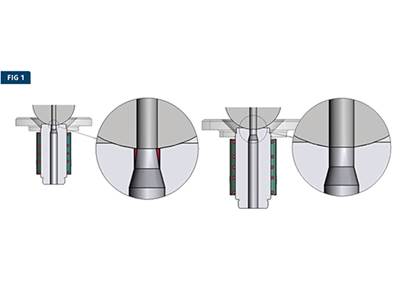

Read MoreTroubleshooting Material Burning In Hot-Runner Systems

Burns in hot runners can be misleading and hard to diagnose correctly. Follow these tips to track down the root cause of your problem.

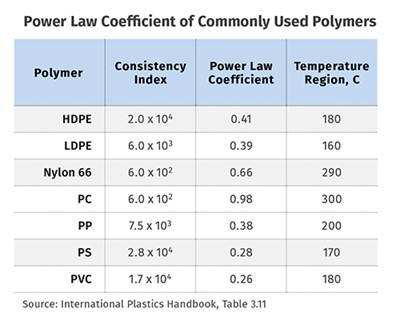

Read MoreEXTRUSION: Another Technique for Controlling Melt Temperature

Flight widths are almost always designed at 10% of the screw diameter. But they can be optimized to reduce melt temperature and perhaps boost output.

Read MoreMATERIALS: The Problems with Single-Point Data

Engineers who are used to working with metals are surprised that plastics cannot operate as close to their yield points as can metals. The yield point is not enough to tell you how the material reacts to stress.

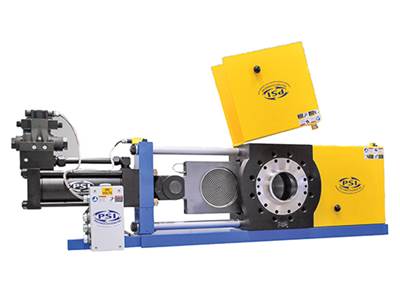

Read MoreKeep Your Screen Changer In the Flow

The screen changer plays an essential role in generating quality extrudate. Here’s what you need to know to keep it functioning properly.

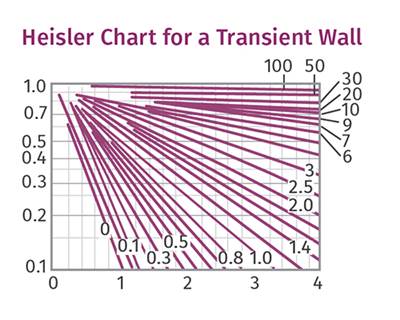

Read MoreEXTRUSION: Cooling: The Critical Function in Extrusion

Figuring out how much cooling your process needs is complicated. But there are ways to approximate.

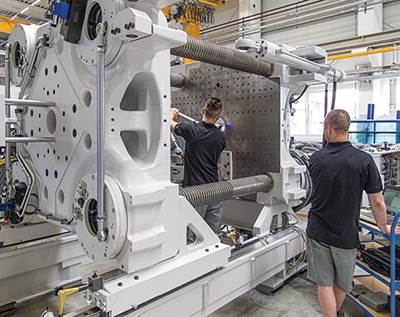

Read MoreINJECTION MOLDING: How to Specify an Injection Molding Machine

With the market percolating, more molders are looking at new presses. This series will discuss what you should consider before writing a check, beginning with the clamping unit.

Read More