processing tips

TOOLING: Clearing Up the Mysteries Of Mold Texture

It’s a subject not widely understood by molders and it affects more than just part appearance.

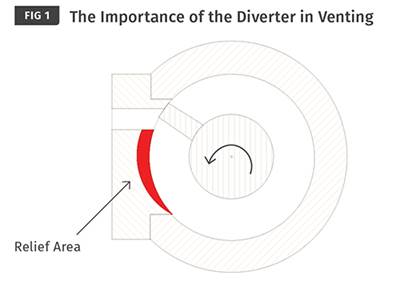

Read MoreExtrusion: What’s the Best Way to Vent?

There are advantages and disadvantages to each, and they must be evaluated before making a decision.

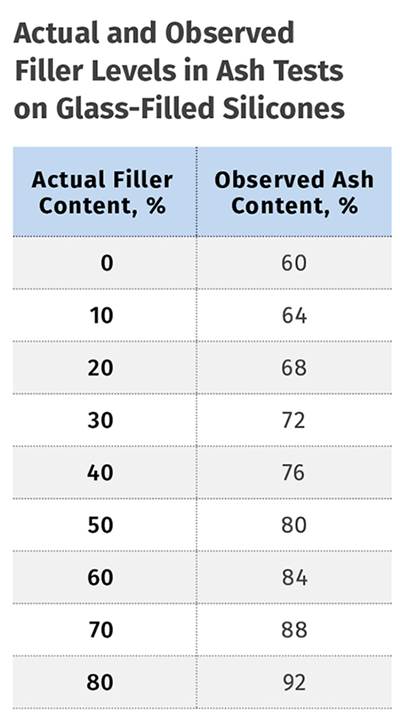

Read MoreMaterials: Analyzing Filler Content

The process is considered simple. But things aren’t always as they seem.

Read MoreFor Better Warpage Simulation, Consider the Whole Molding Process

Which way will it warp, and how much? To get an accurate prediction, you have to look at the whole mold and the whole process, over several cycles.

Read MoreTOOLING: What You Can Do About Mold Buildup

It depends on the materials and additives you use, and the kinds of mold detail, but adequate venting, not overheating the material, and mold coatings are your best defenses.

Read MoreINJECTION MOLDING: The Trouble with Mismatched Nozzle Tips & Sprue Bushings

It happens more than most molders realize and can cause a host of molding problems. Here’s what to look for and how to fix it.

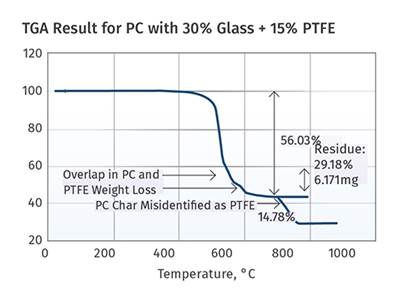

Read MoreMATERIALS: Analysis Gone Wrong: Part 2

But even misinterpreted tests can yield an approximation of the real composition of the material.

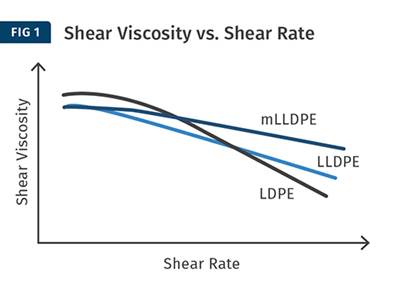

Read MoreCoextruding Blown Film Needs Deeper Understanding of Resin Rheology & Die Design

More film processors are investing in lines with nine or more layers. With more resin possibilities and combinations coming into play, it’s important to learn more about material rheology and compatibility, as well as die design.

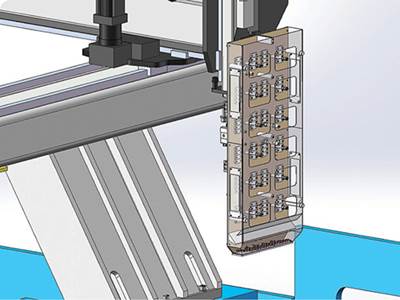

Read MoreRobot End-of-Arm Tooling: Making a Big Difference

Often overlooked as a small part of an automation system, clever end-of-arm tooling techniques and designs can improve part quality, heighten efficiency, and eliminate headaches for any molder.

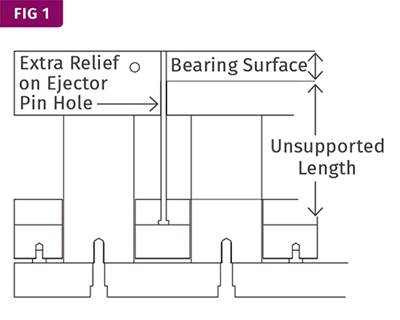

Read MoreTOOLING: Ejectors: Watch That ‘Unsupported Length’

It may be an unfamiliar term, but it’s the key to preventing ejector-pin deflection and breakage

Read More