processing tips

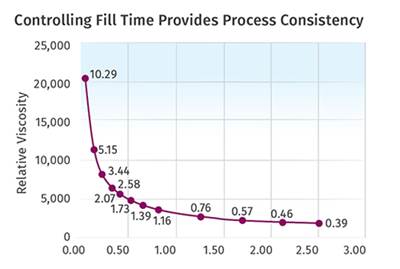

INJECTION MOLDING: Get Control Over Barrel Zone Temperature Override

Poor temperature control results in an erratic melt stream and process. Here are some tips on how to get things under control.

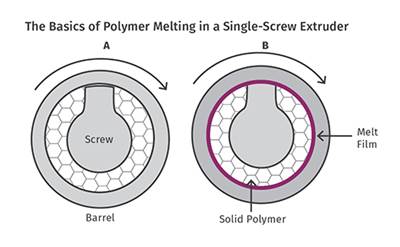

Read MoreEXTRUSION: Melting 101

Learn the basics on how polymer melts in a single screw. Barrel temperature plays less of a role than you might think.

Read MoreINJECTION MOLDING: Develop Guidelines—Not Strict Procedures— For a Robust Molding Process

‘Fool-proof’ dos and don’ts will prove foolhardy in a process with so many variables. You aren’t slinging burgers.

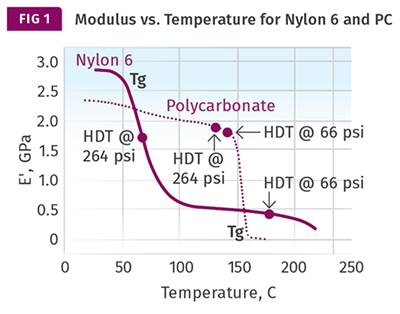

Read MoreMATERIALS: The Problems with Single-Point Data, Part 7

The industry can choose between continuing to perform DTUL tests that provide single points that are part of a curve never seen, or perform the test that provides the entire curve.

Read MoreGet Back to Basics On Water-Cooling Equipment

Neglecting your plant water systems can result in inefficiencies and downtime. Follow these tips when you get new equipment on stream or to maintain what you’re already running.

Read MoreSolve Venting Problems on Twin-Screw Compounding Extruders

Compounds must be free of voids and volatiles or else the material will cause subsequent processing problems. Here’s how to ensure your venting is effective.

Read MoreWhy & When Should You Re-Crystallize PET Scrap?

Whether you’re blow molding PET bottles or extruding APET sheet, you’ll produce amorphous scrap in the process. How you handle it will impact your production costs. Re-crystallizing it will help.

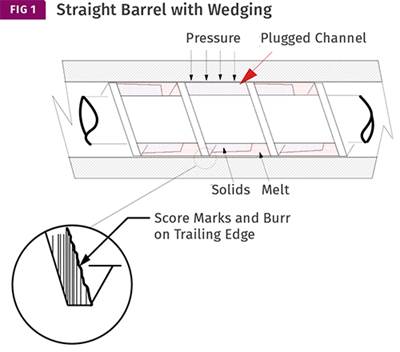

Read MoreEXTRUSION: The Two Main Causes of Screw Wear

Wedging and misalignment are often confused with each other when inspecting a worn screw.

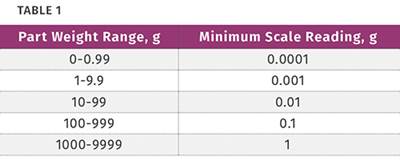

Read MoreINJECTION MOLDING: Gate-Seal Testing Done Right

Follow these 16 steps to perform the experiment and learn what is best for your part and process.

Read MoreWhat You Need to Know to Make World-Class Stretch Film

Advances in materials, feedblock/die technologies, and winding can help processors develop more sophisticated cast-stretch products.

Read More