processing tips

How to Duplicate a Process From Press to Press

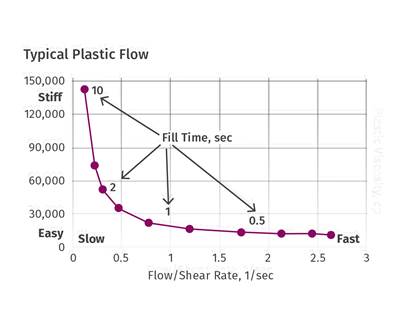

To adopt the right approach you must distinguish between machine and plastic parameters.

Read MoreThe Need for Generalists: Part 4

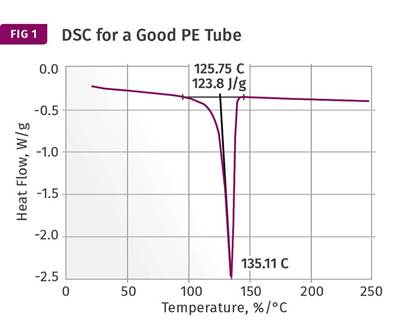

Solving problems generally requires distinguishing good samples from bad ones. But that can become clumsy when one person runs the test while another analyzes the data.

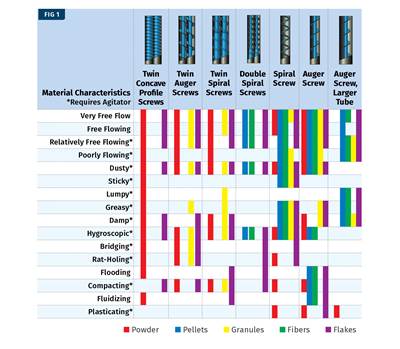

Read MoreOptimize Feeding to Get More Money in Twin-Screw Compounding

Follow these practical examples to improve the feeding efficiency and productivity of your process.

Read MoreUse Molding Simulation To Avoid Surface-Finish Defects

It’s not just for successful mold filling and cooling. Simulation can help predict and overcome cosmetic defects in molded parts.

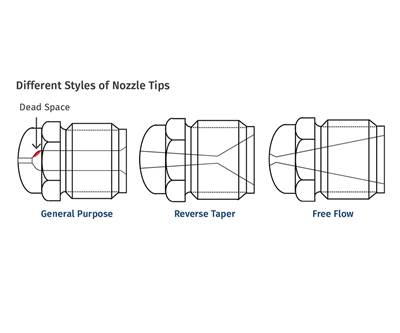

Read MoreHow to Pick, Remove, and Replace a Nozzle Tip

This small component can cause big problems. Here’s my procedure for picking and replacing yours.

Read MoreThe Need for Generalists: Part 3

In failure analysis, there is a tendency to gravitate to a few common test protocols. But this approach can result in a mismatch of techniques to the problem.

Read More15 Things to Know About Servo-Driven Injection Machines

Drive technology for injection molding machines has been continuously evolving, and servo motors have become widely used in a variety of roles. Here’s what molders need to know about today’s servo drives in terms of cost, performance, maintenance, and training.

Read MoreHow to Collect and Interpret Process Data in Extrusion: Part 2

In this second of three installments, the focus is on the crucial element of melt temperature.

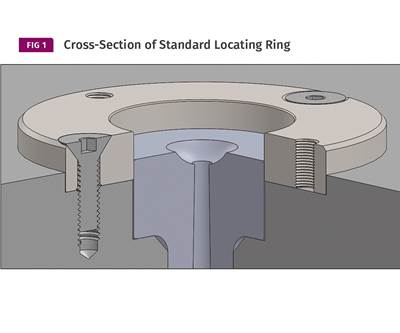

Read MoreWhat You Need to Know About Locating Rings: Part 1

Selecting the right locating ring and putting it to good use takes a lot of thought.

Read MoreExtruding with Fillers

You can use the reference point from processing unfilled polymer to determine whether you can run filled resin on your current system.

Read More