processing tips

Materials: Cycle Time: Science vs. Rules of Thumb—Part 2

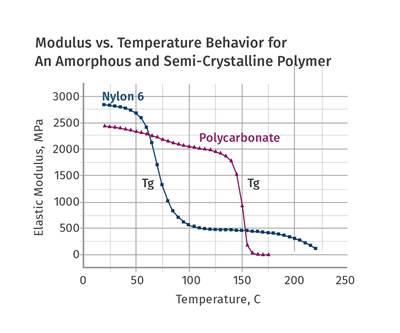

Understanding cooling—how a given material develops modulus as it solidifies—requires access to data that provides some insight into the relationship between modulus and temperature. Dynamic mechanical analysis is a helpful tool.

Read MoreUnderstanding Low-Rate Feeding for Continuous and Batch Processes

Molders and extruders that need to feed tiny amounts of material to their process require precision in both the material being fed and the equipment doing the dosing. When a shot size consists of three pellets, there is no margin for error.

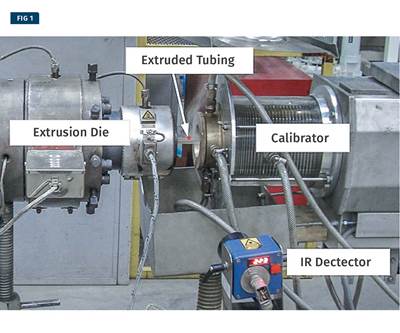

Read MoreHow to Collect and Interpret Extrusion Process Data; Part 3

In this final installment, learn how process data can be used to identify and fix extrusion issues.

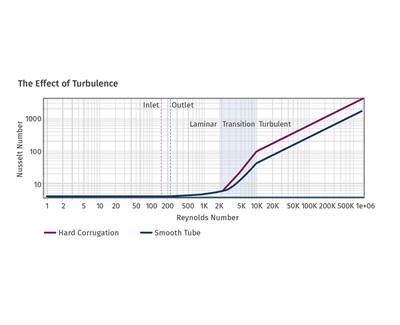

Read MoreExtrusion Cooling: It’s All About Turbulence

Regardless of what you are extruding, in order to maximize cooling you need to generate turbulence at the heat-exchange surface.

Read MoreInjection Molding: Are You Using More Than 65% Of Your Barrel Capacity?

If you are, you are inviting Murphy—as in trouble—to the party.

Read MoreHow to Solve Common Ultrasonic Welding Problems

Understand and address the likely origins of welding problems to keep production on track.

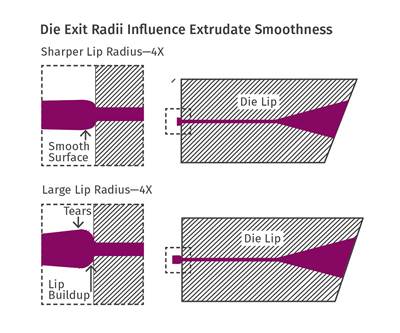

Read MoreSharper Dies Make for Smoother Extrusions

Dies that have a radius at the exit will result in poorer surface finish.

Read MoreClamp Tonnage: More Is Better...Right?

Determining the correct tonnage provides a foundation that must be rock-solid to avoid flash and damage. But applying excessive force can create problems with the part, mold, and machine.

Read MoreCycle Time: Science vs. Rules of Thumb, Part 1

What temperature must the polymer reach so the part can be ejected from the mold? Here, more than for any other variable, ‘rules of thumb’ unfortunately prevail.

Read MoreBlock Cavities and Keep Molding

It goes against conventional wisdom, but molding with blocked cavities can be done while maintaining quality with the help of appropriate in-cavity sensors and process-control software.

Read More