processing tips

Extrusion: A Simple Way to Evaluate Your Screw Performance, Part 2

A hand-held calculator and some basic equations can help determine whether your screw is up to snuff.

Read MoreInjection Molding: Safety First—Know the Compatibility of Different Resins

Certain materials don’t play well together when mixed. So it’s best not to. Here are some guidelines.

Read MoreRapid Heat & Cool Molding Evolves to Meet Industry Challenges

Technical capabilities of the process have advanced to erase former cycle-time penalties, and ongoing developments address creation of a materials database and new applications in hybrid composite injection overmolding.

Read MoreInjection Molding: Process Documentation Is Crucial to Making ‘Identical’ Parts

Use a machine/mold setup sheet to document plastic parameters and use them on any acceptable machine into which the mold is placed.

Read MoreTooling: Clamp Pressure and Cavity Land Area

What you need to know to prevent flashing and mold damage.

Read MoreInjection Molding: A Practical Approach to Calculating Residence Time

Toss the formulas. The best way to determine residence time is to conduct a simple experiment.

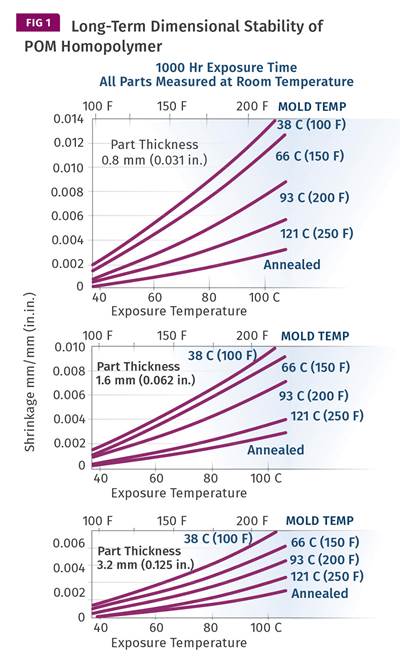

Read MoreA Processor's Most Important Job, Part 5: POM Polymers

Using a mold temperature above a polymer’s Tg ensures a degree of crystallinity high enough to provide for dimensional stability, even if the part must be used at elevated temperatures. But POM is an exception. Why?

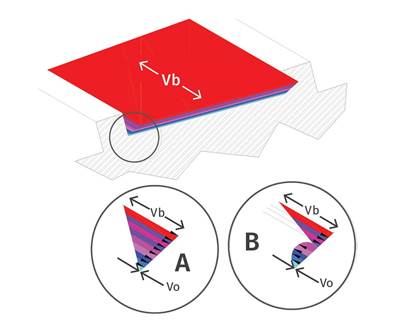

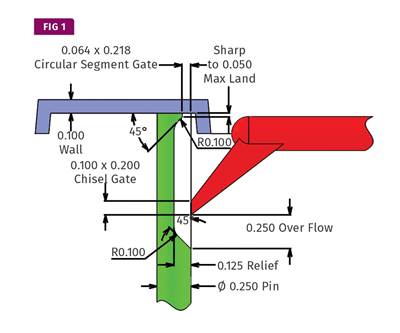

Read MoreTooling: What You Need to Know About Jump Gates

Many molders don’t care for jump gates because they have to process around them. But here are some tricks of the trade.

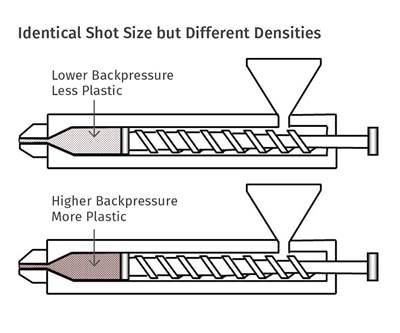

Read MoreInjection Molding: How Backpressure Adjustments Influence Shot Size

Raising backpressure results in increasing shot size, which can cause a host of other problems.

Read MoreGW Plastics Bets on Metal 3D Printing

Conformal cooling is goal of big investment at U.S. mold facility.

Read More