processing tips

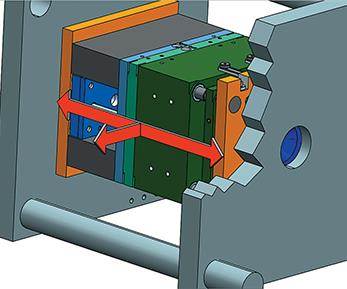

TOOLING: The Tool’s Impact On the Molding Process

Flash, venting, cooling, gating, or sticking problems? Better to fix the tool than distort your process.

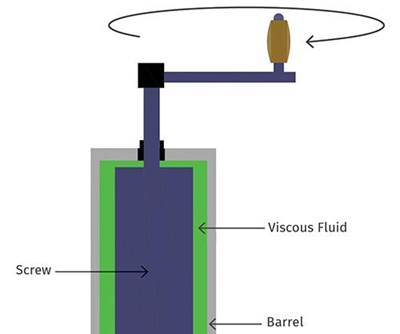

Read MoreEXTRUSION: How Slow Can You Go?

Larger screws designed for high outputs will generate a variety of problems if run too slowly. Here’s why.

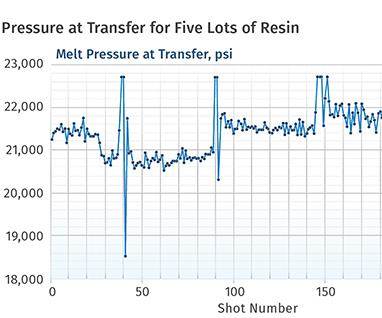

Read MoreINJECTION MOLDING: Processing Nylon…and Other Problems

As moisture content in this and other hygroscopic resins varies, so will your viscosity and process. Here’s how to deal with these issues

Read MoreIs Your Granulator Helping You Maximize Your Profit?

It’s easy to take a scrap granulator for granted. Many people do. But getting the most value out of your production scrap requires both a granulator design and a preventive-maintenance program that are appropriate to the way you use the granulator.

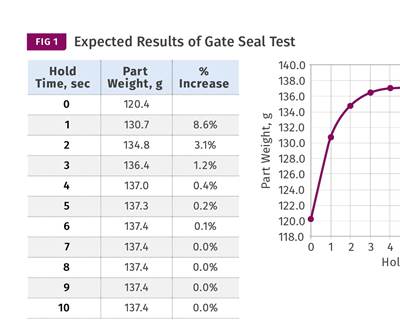

Read MoreINJECTION MOLDING: Gate Freeze Study: Danger in a Name?

The test actually determines the hold time needed to mold repeatable parts, and it should be done regardless of whether the gate freezes or not.

Read MoreCyclic Olefin Copolymer: Alternative Resin For Medical Packaging

With Barex production winding down, processors serving the medical market are eyeing replacements. Some have already commercialized new packages with COC.

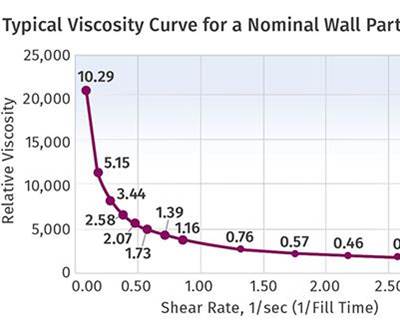

Read MoreINJECTION MOLDING: Do You Need to Profile Injection Velocity?

Look at the parts. If the answer is yes, the on-machine viscosity curve can help.

Read MoreA Film Processor’s Guide to Understanding Materials & Equipment

Process engineers need to have a fundamental understanding of three areas: the material properties, the basic design parameters of the extrusion equipment, and the process window of the equipment.

Read MoreINJECTION MOLDING: Improving Barrel-Temperature Measurement and Control

Proper thermocouple placement and contact area are crucial, as is wire maintenance. But remember that barrel temperature and melt temperature are not the same

Read MoreEXTRUSION: Managing Regrind

Reusing scrap is a necessary evil. But be aware of the negative impact scrap has on properties and extrusion efficiencies. Start by developing a regrind-usage program.

Read More