Sheet Extrusion

Study May Boost Prospects For Single-Screw ‘Elongator’

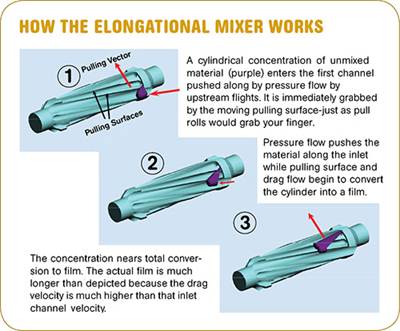

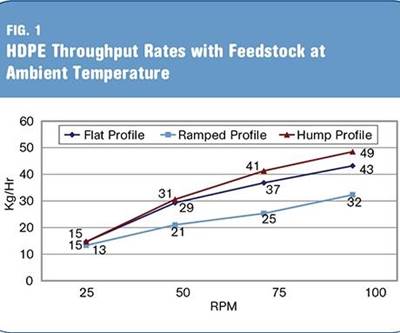

Dow Chemical Co., Midland, Mich., weighed in at last year’s SPE ANTEC with a paper discussing results of experiments they conducted on a novel elongational mixing device developed by Randcastle Extrusion Systems

Read More'Dryer-less' PET Sheet System

Processing Technologies International (PTi), recently took the wraps off its “dryer-less” twin-screw PET sheet extrusion system at its headquarters in Aurora, Ill.

Read More'Beastly' Line Adds Sheet Extrusion Flexibility

They call it the “The Beast,” a new sheet line installed recently by custom extruder Rowmark in Findlay, Ohio (rowmarkllc.com). It’s nearly as long as the new 175 x 75 ft facility built to house it.

Read MoreWhy—and How—to Baseline Your Extruder

If you don’t baseline your extruder, then how are you going to set realistic expectations for its performance? Here's how to get going.

Read MorePhysically Foamed HIPS Is New Factor in Rigid Packaging

Relief for escalating costs of packaging materials and an opportunity to address sustainability goals are two factors that have helped attract global attention to a new physical foaming technology for HIPS packaging.

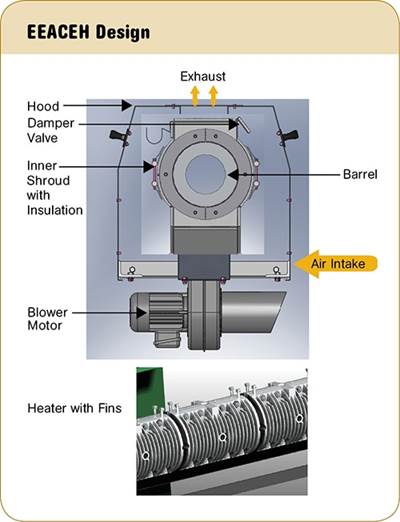

Read MoreNew Barrel Heater/Cooler Saves ‘Juice' to Run an Extruder

New, patent-pending design is said to reduce both radiant and convection heat losses.

Read More'Green'...And Microwaveable Too

New technology from Teknor Apex Co., Pawtucket, R.I., eliminates a property tradeoff that could allow polylactic acid (PLA) to supplant polystyrene and polypropylene for microwavable frozen-food trays, lids for hot beverage cups, and carry-out containers.

Read MoreDetermining the Maximum Machine Direction Orientation (MDO) Possible for Sheet

Given a set film thickness, width and material, how to you determine how much machine-direction orientation (MDO) is possible for a sheet.

Read MoreDead Screw Talking

There's a lot you can learn by conducting a post-mortum examination of your screw.

Read MoreLook Before You Leap: When Direct Extrusion Makes Sense

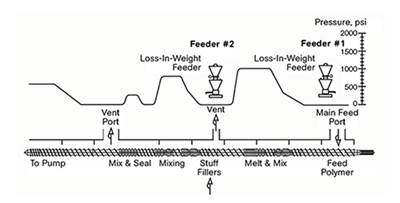

The process offers great opportunities to extrude a better product at less cost, but it’s not for everyone. The formulation, product mix, and anticipated volumes must be carefully assessed to determine whether DE is the preferred manufacturing methodology.

Read More