Testing

Non-Contact IR Analysis Simplifies On-Line Quality Control

A new method of mid-infrared analysis allows on-line monitoring of both the composition and physical properties of a plastic while it is being compounded or extruded.

Read MoreUltrasonic Imaging Finds Voids, Cracks and Bonding Defects

As material costs climb, acoustic micro-imaging (AMI) is increasingly being used for non-destructive inspection and quality control of microelectronic components and assemblies, adhesive and welded bonds, solid part walls, and other applications where bond integrity, cracking, or voids are an issue.

Read MoreNPE 2006 News Wrap-Up: Testing and QC--New Lab Instruments Stress Affordability and Convenience

Thermal and mechanical testers, color and appearance sensors, vision inspection devices and CMMs—the NPE had them all in more compact, economical, and easy-to-use models.

Read MoreLaser Scanning Saves Time and Money for Digitizing Parts and Molds

Blow molded product designers and moldmakers are finding laser scanning to be a fast, accurate, and cost-effective method to replicate molds and create new designs for highly contoured and complex parts such as beverage bottles.

Read MoreA Custom Molder Takes the Next Step

The question John Winzeler keeps asking is, “How do you take the next step?” In the last two decades, he has transformed the Chicago metal-stamping company he inherited from his father into a high-tech specialty molding business focused only on plastic gears.

Read More3D Part Inspection Is a Snapshot Away

A non-contact inspection system uses digital photography for accurate three-dimensional measurement of plastic parts.

Read MoreWhat to See at NPE 2006:Testing and QC

There’s never been a better time to outfit your lab or QC inspectors with testing and measuring instruments.

Read MoreNPE 2006 News Flash

Injection MoldingSimplified Hot Runners Save Time & CostA new lower-cost hot-runner alternative to valve gating is suited to less critical cosmetic applications where users need predictable and reliable gate opening but not sequential gate operation.

Read MoreNanocomposites Do More With Less

For skeptics who may doubt that nanocomposites have yet proven themselves commercially viable materials, last year’s Nanocomposites 2005 Conference in San Francisco presented plenty of evidence that “nanos” are beginning to live up to their promise.

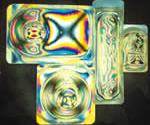

Read MoreStress: Diagnose It Before It Ruins Your Parts

Residual stress is an inherent result of plastics manufacturing processes and occurs when molten polymer is cooled and shaped.

Read More