Testing

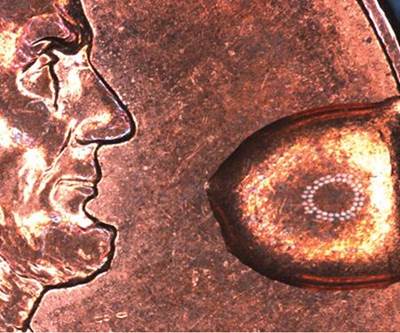

APPLICATION: Optical Sorter Boosts CarbonLite's RPET Quality

An Buhler Sortex optical sorting system is optimized for RPET bottling operation.

Read MoreMelt Flow Rate Testing–Part 8

Here are the steps to take in cases where the MFR is not provided by the polymer supplier.

Read MoreTESTING/MEASURING: Laser Design Distributes Tomelleri Portable CMMs

Laser Design is now the master North American distributor for the Space Arm coordinating measuring machines from Italy's Tomelleri Engineering.

Read MoreK 2013: More Efficient, Flexible & User-Friendly Auxiliaries

It’s hard to generalize about auxiliary equipment, but a few trends stood out at K, including: greater energy efficiency, ease of maintenance and cleaning, controls that provide more real-time and historical process information and greater ease of use.

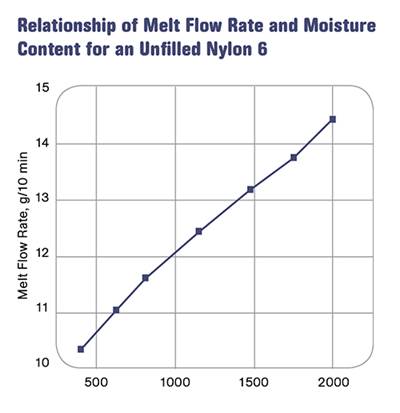

Read MoreMelt Flow Rate Testing—Part 5

There are two points in the manufacturing supply chain where a determination of average molecular weight (MW) is important. The first is when the material is first received by the molder. The second is after molding.

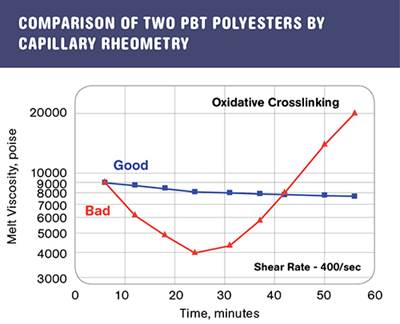

Read MoreMelt Flow Rate Testing—Part 4

Few molders perform the test in-house. Of those that do, most don't understand why they are doing it or what they are measuring.

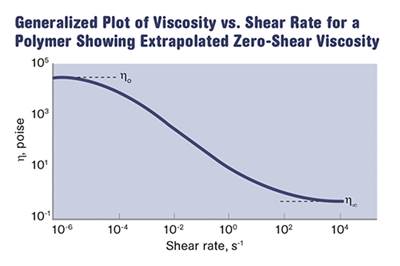

Read MoreMelt Flow Rate Testing—Part 3

There is a well-established relationship between something called the weight-average molecular weight of a polymer and a parameter known as the zero-shear viscosity.

Read MoreA Processor’s Advice on How to Get Moisture Testing Right

Follow these four steps to ensure your results are on target.

Read More