Melt Flow Rate Testing—Part 5

There are two points in the manufacturing supply chain where a determination of average molecular weight (MW) is important. The first is when the material is first received by the molder. The second is after molding.

How should melt-flow-rate (MFR) testing be used? There are two points in the manufacturing supply chain where a determination of average molecular weight (MW) is important. The first is when the material is first received by the molder. The second is after molding.

Checking the incoming material is useful because it establishes that the material was produced within the specified range for the MW of the product. If a certification is provided with each lot of material, one of the few properties that is likely to be listed is the MFR for that lot, along with a minimum and maximum specification value. Most molders simply check the certification and file it, assuming that the value is correct. However, there are several good reasons for verifying the number in-house.

First, the MFR value published on the certification is often a snapshot from one point in a production run that may last for hours or even days. As with any manufacturing process, there is variation in resin polymerization and compounding, and the sample that was tested to provide the number on the certification may not be representative of the material that is received by the molder.

Second, routine checking tends to create an open line of communication between the molder and the material supplier or distributor. This is always useful when trying to resolve problems or optimize the consistency of a material. I have had the experience of working with material suppliers to narrow a MFR specification range to improve the consistency of molded part performance.

That was 20 years ago, and the responsiveness of resin suppliers today may not be what it was then. But the point is that if we had not been collecting data in-house and correlating it to the feedback we were getting from our customers about the functionality of the molded parts we were shipping, we would not have known what to ask for.

Third, accuracy is always a concern for those who are new to MFR testing. Being able to check in-house results against certification values or a certified sample of material helps the people performing the tests build confidence in their technique.

While these tests focus on the quality of the raw material, the tests on the polymer in the molded parts is a reflection of the quality of the molding process. Small changes in the MFR of the polymer during the molding process are to be expected. While there are exceptions, the MFR typically increases during processing, indicating that the MW is decreasing under the influence of the heat and shear of processing. There is little consensus regarding the allowable increase in MFR between raw material and molded part, although the numbers typically quoted fall into a fairly narrow range, between 20% and 50%.

The largest amount of work done to answer this question more precisely was performed back in the 1970s by the major material suppliers. These companies at the time were the source for all of the good research and advice regarding material properties and processing. By correlating property retention to the change in the way the material flows at the low-shear conditions of the MFR test, researchers came up with guidelines for processors.

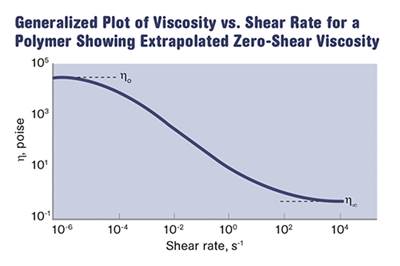

However, at that time much of the work was done by measuring the actual melt viscosity rather than the MFR. This is a subtle but important difference. While the MFR tester is not an appropriate instrument for making true measurements of viscosity, it is possible to correlate the flow rates measured in a capillary rheometer to those observed in a MFR tester. By establishing an empirical equivalence, the researchers created instrument constants for the MFR tester that could be applied to various materials in order to report the result using viscosity units. To this day, the certifications for some commercial grades of raw material are still reported in viscosity units (poise) rather than a true flow rate (grams/10 minutes).

Using these viscosity measurements, the upper limit for an allowable change from raw material to molded parts was associated with a viscosity reduction of 30%. This has often been restated as a maximum allowable increase in MFR of 30%. However, these two statements are not equivalent. MFR is the reciprocal of viscosity. A 30% viscosity reduction equals a 42.9% increase in MFR. This has been rounded off to 40% to provide a safety factor. This change translates to a 10% reduction in the polymer’s weight-average MW.

People tend to adjust these guidelines in a somewhat self-serving way. Material suppliers will often quote values of 25-30% for maximum recommended increase in MFR during processing, in order to shift the burden to the processor. Some processors will lobby for a number as high as 50% to give themselves a little more allowance for the things that happen during processing.

And one large OEM holds its molders to a maximum allowable increase of 20% and sets this as an acceptance criterion for all shipments. The OEM’s argument is that if the number exceeds 20% it begins to see failures during its qualification tests. Yet the change in MW associated with a 20% MFR increase is quite small. If parts fail under these circumstances, it is a reflection on the part design and perhaps the nature of the qualification tests, not the process.

As with all guidelines, it is easy to over-interpret their significance. By setting a 40% upper limit for MFR increase during processing, we are not saying that if the value reaches 41% all the parts will fail, and if it stays at 39% everything will work as planned. The functionality of a product always depends upon a complex interaction of design, material properties, processing, and application conditions.

But what can be demonstrated is a decline in material properties as the change in MFR due to processing increases. It is common to receive two parts, one identified as “good” and one that has failed. Tests often show that both parts display an excessive increase in MFR but the change for the part that is still working properly is much smaller than for the one that has failed.

This simply shows that the part design is robust enough to compensate for some level of degradation. But the fact that the MFR of the two parts can vary so much is also an indication that the process conditions used to produce the parts are not consistent. This is typical; you cannot manage what you don’t measure. And too few processors measure MFR before or after processing.

About the Author

Michael Sepe is an independent materials and processing consultant based in Sedona, Ariz. with clients throughout North America, Europe, and Asia. He has more than 35 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting, and failure analysis. Contact: (928) 203-0408 mike@thematerialanalyst.com.

Editor’s note: You can read the next part by clicking here.

Related Content

The Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MoreHow to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreMelt Flow Rate Testing—Part 3

There is a well-established relationship between something called the weight-average molecular weight of a polymer and a parameter known as the zero-shear viscosity.

Read MoreMelt Flow Rate Testing—Part 4

Few molders perform the test in-house. Of those that do, most don't understand why they are doing it or what they are measuring.

Read More

.jpg;width=70;height=70;mode=crop)