Additive Manufacturing: Materials for ‘Real-World’ Parts

Developments in materials have helped pave the way for processors to make ‘real world’ parts from what is collectively known as 3D printing. Here’s a comprehensive review of the materials available.

The type and range of materials available for additive manufacturing with plastics help determine how this emerging group of technologies—often referred to collectively as 3D printing—is being used by industry. Additive manufacturing technologies have long been used for so-called rapid prototyping, and materials development was formerly focused on making “functional prototypes” with properties representative of production parts. But the forefront of innovation today is aimed at additive production of “real-world” parts. The attractions are cost-effective production of short runs—even single parts—without tooling and with lead times as short as a few hours, as well as the potential for making complex shapes that cannot be produced (without assembly steps) by any other process.

The question for interested processors is what sort of “real-world” materials are available for true additive manufacturing. Selective laser sintering (SLS) and fused deposition modeling (FDM) are currently the only processes used for additive manufacturing in production. In general, these technologies make sense where production volume is low and product value is high. Current and potential applications range from aerospace interior components to automotive parts, medical implants, customized consumer products, and sporting goods.

The terms additive manufacturing and 3D printing are often used interchangeably, but industry is increasingly adopting the former as more accurately descriptive. In general, 3D printers typically cost in the $10,000 to $50,000 range, have typical build envelopes of 10 x 10 x 10 in., and can use a couple of general-purpose materials, typically photopolymers, with medium-range mechanical and thermal properties. As they have evolved so far, 3D printers have shown themselves to be best for form-and-fit prototypes and some light-duty functional testing of parts.

In contrast, industrial 3D production systems typically start at $50,000 and can reach over $500,000 for the higher-end SLS systems. They normally have a build envelope greater than 1 x 1 x 1 ft and a repertoire of least eight to 10 materials with premium-grade mechanical and thermal properties that can be customized to specific end-uses. These include highly engineered thermoplastics like PEEK and PEI, including grades reinforced with glass fiber and, most recently, carbon fiber. These materials are well suited to functional testing and field testing, product trials, and creating manufacturing tools and finished goods. New materials have surfaced recently for these processes, as have some advances in 3D printing.

NEW MATERIALS FOR SLS

The SLS process, offered by 3D Systems, Rock Hill, S.C., and Germany’s EOS GmbH (U.S. office in Novi, Mich.), has been by far the most popular for making real-world plastic parts, according to Terry Wohlers, Fort Collins, Colo., a well-known expert and consultant in this field. SLS allows the construction of structures from powdered thermoplastics, which are consolidated (sintered) by moving laser beams. SLS is touted for the quality, reproducibility, and mechanical strength of components it produces.

Wohlers points out that most additive manufacturing of plastic parts has been in aerospace, where Boeing, for example, has built tens of thousands of parts for 10 different aircraft using SLS for non-structural environmental airflow ducts, brackets, clips, and electrical boxes. Another use of SLS is in motor sports such as motorcycles for smaller-volume runs of custom-styled parts such as speedometer housings, shrouds, and farings that replace metal or injection molded plastics.

While not for high-volume automotive jobs, both SLS and FDM processes are being considered by luxury sports-car companies like Maserati and Lamborghini. “SLS produces strong parts and is a relatively fast process. But no matter what industry you serve, the best scenario is where you are doing major redesign that results in consolidating parts, as is the case with parts made by Boeing,” says Wohlers.

Nylon 12 and 11 have remained the base materials for the majority of SLS powders for many years. Both 3D Systems and EOS offer a range of nylons, including flame-retardant, impact-resistant, glass-filled, aluminum-filled, and carbon-fiber grades. EOS also offers a PEEK (polyaryletherketone).

A little over a year ago, the Rhodia unit of Solvay Engineering Plastics (U.S. office in Alpharetta, Ga.) launched the first range of nylon 6 powders developed specifically for SLS. Sinterline nylon 6 powders reportedly produce SLS parts that display heat resistance and stiffness similar to injection molded nylon 6.

In France, Solution F/E2R, a company specializing in engineering and rapid-prototyping techniques for recreational vehicles and aerospace applications, has used Sinterline to manufacture parts such as air-intake ducts and brake-fluid tanks. The excellent surface finish offered by Sinterline is expected to help broaden the range of SLS parts, according to Hermann Hanning, technical manager of LSS Laser Sinter Service GmbH in Germany, one of Europe’s rapid-prototyping specialists. He expects the material will quickly establish itself for automotive and electronic prototyping and short-run applications.

EOS recently added two new materials to its roster. One is PA 2241, a flame-retardant nylon 12 for processing on its Eosint P systems. This material is “replenishable,” meaning that leftover powder after sintering a part can be used for another part. “Replenishability” cuts manufacturing cost significantly, though EOS recommends use of at least 60% fresh powder.

The new grade offers a higher level of flame resistance than EOS’s previous grade (PA 2210 FR) and also has improved mechanical properties, including a tensile strength of 49 MPa (7107 psi) and elongation at break of 15%. It is aimed at aircraft interior parts such as ventilation ducts and outlet vents.

The other new EOS grade is PEBA 2301, a soft copolyester TPE for use on certain Eosint P and Formiga P systems. It has an elongation at break of 200% together with good rebound elasticity and fatigue resistance in the -40 to 194 F range. Target applications include winter-sports accessories such as impact protectors; consumer-goods housings; automotive fittings such as grips and corner/edge or door-lock components; medical instrument grips; industrial grips and handles; and flexible cable holders and sheaths.

Oxford Performance Materials (OPM), South Windsor, Conn., has made a powder of its own Oxpekk PEKK (polyetherketone-ketone) engineering resin suitable for use on EOS equipment. PEKK shares some of the qualities of better known PEEK, including high mechanical strength, heat resistance, and biocompatibility. However, OPM CEO Scott DeFelice says the PEKK molecule offers greater latitude for tweaking to produce customized materials for different biomedical applications.

In fact, OPM recently received FDA certification for its own SLS application of PEKK—the OsteoFab Patient Specific Cranial Device, a customizable implant designed to restore voids in the skull caused by trauma or disease.

FDM MATERIALS ADVANCE

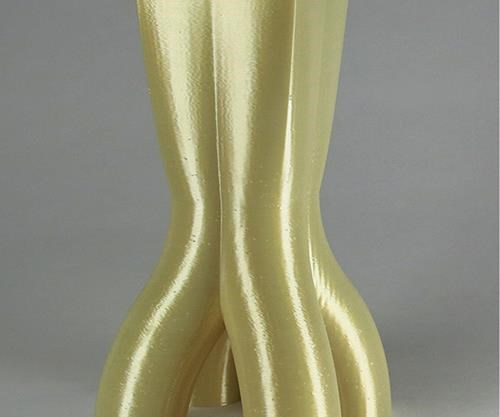

The FDM process (trademarked by Stratasys, Eden Prairie, Minn.) and its variants, which are referred to as fused filament fabrication (FFF), use standard and engineering-grade thermoplastic filaments to produce functional parts. The technology builds parts layer by layer by heating fine thermoplastics filament to a semi-liquid state and extruding it along computer-controlled paths. Like all other 3D printers, except for SLS, FDM and FFF use a build material and sometimes also a wax-like or gel-like support material, which acts like a scaffolding for building complex shapes. Once the part is fully built, the supports are either broken away or dissolved in detergent and water.

Stratasys’ range of FDM materials include several types of ABS filaments, including opaque and transluscent grades in various colors, plus impact-resistant, static-dissipative, high-heat, and biocompatible grades. Also available are filaments of PC/ABS, PC, sterilizable PC and PPS, and a flame-retardant, low-smoke, low-toxicity PEI (based on Ultem 9085 from Sabic Innovative Plastics, Pittsfield, Mass.).

Late last year, Stratasys launched a tough, unfilled FDM nylon 12, the first nylon designed specifically for its Fortus 3D FDM equipment system, which is aimed at applications requiring repetitive snap-fits, high fatigue endurance, strong chemical resistance, high impact strength, or press-fit inserts. Stratasys says the new FDM nylon 12 creates tougher, more flexible unfilled nylon parts than those made with other additive manufacturing technologies. The new material’s elongation at break surpasses that of other nylon 12 3D printing materials by up to 100%. It is exponentially more fatigue resistant, with three times higher impact strength (notched and unnotched Izod) and much lower moisture absorption than nylons 6, 66, and 610, so it can be used in places where other nylons fall short. The material is paired with a new soluble support material, SR110, which has been optimized for FDM nylon 12 and is easily washed away.

Says Fred Fischer, Stratasys engineering manager, “For us, the new nylon 12 represents a breakthrough because FDM used to be best for amorphous versus semi-crystalline plastics. We were able to make the new nylon 12 compatible with FDM technology, so now we see that other semi-crystalline plastics such as PEEK, PP, and other nylons that customers have been seeking for years look more feasible with FDM. We are looking to make significant improvements in the materials we bring to market by focusing on high-performance, high-value applications that will address a vast portion of injection molded products.” To that end, Stratasys has begun to collaborate with industry (see sidebar below).

Fischer says Stratasys elected to work on nylon 12 first because of its use in automotive components and aerospace jigs, tooling, and fixtures. He also sees nylon 12 being used for functional prototypes of consumer goods such as drills and other construction tools.

NatureWorks, LLC, Minnetonka, Minn., and Ireland’s 3Dom Filament Ltd., recently announced their collaboration to support 3D printing by combining NatureWorks’ Ingeo PLA resins with 3Dom’s filament manufacturing processes for use on FDM units. 3Dom’s team has more than a decade of technical experience with Ingeo PLA and will supply its entire monofilament family with the Ingeo logo. Over the last year, 3Dom developed a process for converting Ingeo into consistently high-quality filaments in all primary colors, with more colors on the way. 3Dom can tailor Ingeo monofilament properties such as stiffness, toughness, and dimensional stability.

NatureWorks’ Dan Sawyer, global leader for new business development, says a couple of companies are starting to use Ingeo PLA filament for small-scale additive manufacturing, but are not speaking publicly at this early stage. Adds Sawyer, “Through some anticipated collaborative efforts, we believe we can foster development of formulated Ingeo solutions that can address a broader cross-section of parts that goes beyond trinkets and toys towards manufactured articles.”

Boston-based startup MarkForged, founded by aerospace engineer Greg Mark, recently announced the development of what is claimed to be the world’s first 3D printer for carbon-fiber composites. It is essentially an FDM-type machine that can print a carbon-fiber reinforced PLA/nylon blend filament.

The compact Mark One machine with a build size of 22.6 x 14.2 x 12.7 in. will soon be available for purchase at a $5000 price tag. The unit has been used to print out a racecar wing with a nylon outer shell and honeycomb structure with a carbon fiber reinforced core. The company expects that it will be explored for prothetics, custom bone substitutes, tools, and fixtures.

NEWS IN 3D PRINTING MATERIALS

Stratasys launched PolyJet Objet500 Connex3, said to be the first multi-color/multi-material 3D printer. Utilizing a form of UVcured inkjet technology, it features a unique triple-jetting capability that combines droplets of three base materials to produce parts with virtually unlimited combinations of rigid, flexible, transparent, and opaque colored materials—all in a single print run. The system allows users to incorporate as many as 46 colors in one prototype. It prints 3D models and parts with the color, durability, and surface finish of end-use products. The materials boast excellent mechanical properties such as tensile strength, elongation at break, and multiple Shore hardness values, which simulate high-performance thermoplastics. It also allows overmolding with durable “digital ABS” materials (ABS-like photopolymer) and introduces new Shore A values for “digital ABS,” ranging from A27 to A95, suitable for consumer products.

Wohlers says this represents a breakthrough in rapid-prototyping and modeling capabilities, as it can produce multi-colored, stronger, and more aesthetic parts for form-and-fit and some degree of functional testing. Fisher says Stratsys has made improvements to its “digital ABS” and aims to make further enhancements in creep resistance and dimensional stability to meet the needs of higher-end rapid prototyping.

3D Systems recently introduced two new engineered photopolymers for its large-format (up to 21-in.-long) ProJet 5000 3D SLA (stereolithography) printer, introduced a little over a year ago. Visijet M5 Black is a strong, flexible, PP-like material that prints high-definition parts with intricate details. It can be used to make functional parts for rigorous testing and high-definition tooling. Its flexibility allows for easy snap-fit assembly while the color makes it well suited for electronics, automotive components, and chic black appliances.

VisiJet M5-X is a strong, rigid SLA photopolymer with “hybrid” ABS/PP-like properties that delivers bright-white, durable parts with resolution comparable to injection molding. Parts made from the material are rigid, making it a good fit for packaging products such as bottles, as well as household plastics, piping, and valves.

An innovation that could dramatically broaden the range of materials available for 3D printing comes from Arburg, the maker of injection molding machines (U.S. office in Newington, Conn.). Introduced at the K 2013 show in Dusseldorf last October, Arburg’s Freeformer inket-type 3D printer is coming to market this year in Europe. It’s designed for production parts, rather than prototyping, which Arbug calls “a thing of the past.” The most unusual feature is that this device incorporates an extruder so that it can use standard injection molding pellets of most thermoplastics, without requiring special formulations or physical form (powders or filaments). The only limitation is on loadings of fillers or fibers, since the melt is dispensed through a 0.2 mm orifice. (For more details, see December '13 Close Up.)

Related Content

What's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

Read MoreWhat is the Allowable Moisture Content in Nylons? It Depends (Part 1)

A lot of the nylon that is processed is filled or reinforced, but the data sheets generally don’t account for this, making drying recommendations confusing. Here’s what you need to know.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

Read MoreRead Next

Headlines from the K 2013 Show

Here’s just a taste of the innovations on display, a selection of the top headlines not covered in our September show preview.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More