Getting Into LSR--Part IV: How LSR Tooling Is Different

Building molds for rubber molding, and specifically liquid silicone (LSR ) injection, can be very challenging.

Building molds for rubber molding, and specifically liquid silicone (LSR ) injection, can be very challenging. Many think of rubber molding as a low-tech process. It’s actually quite the opposite. In many—if not most—cases, molds for LSR require much more precision and expertise than molds for thermoplastics. (Part I of this series, in June 2010, covered LSR materials. Part II, in Aug. 2010, covered the injection machine. Part III, in Sept. 2011, covered mixing/metering systems.)

PREVENTING FLASH

Both thermoplastic and LSR molds can have very complex geometries. The major difference between them is the requirements for fit and relate between cavity inserts. Many thermoplastic materials can be molded with limited flash using fits between inserts of up to 0.002 in. But many LSRs will flash even with fits as tight as 0.0001 in. or less. This fit requirement necessitates a different level of engineering, machining, and processing precision.

A simple example of fit and relate differences between LSR and thermoplastic injection molds is the use of ejector pins. Straight-wall ejector pins are commonly used in plastic molds. The pins can cross over the parting line on some parts, so that half the ejector pin is on the part and half is on the parting line shutoff. In thermoplastic molding with this design, there is typically no flash. Ejector pins can be used in LSR molds but they must have a tapered shutoff and can’t invade the parting-line shutoff area. Any minute amount of debris or rubber that builds up on the ejector valve seat will cause process failure.

Another special characteristic of LSR processing is the requirement for vacuum. Even though thermoplastic materials can create outgassing during the molding process, the mold will normally have enough gaps (vents) in the fit and relate areas to release these gases along with the air contained in the cavity area. What’s more, LSR molding requires a chemical curing process. Liquid silicone typically comes in two parts. One part has a catalyst and the other has the crosslinker. As these two components mix a chemical reaction takes place that can create some gas. It is important to remove any air from the cavity before injection to ensure that the mold can properly vent the gases evolved during curing. With the very close fit of mold components to prevent flashing, proper land venting has to be incorporated into the design to allow air to escape from the cavity during filling. This venting should be controlled to millionths-of-an-inch depth tolerance if the rubber parts need flash to be controlled within tight specs.

One other difference between thermoplastic and LSR mold designs is in temperature control. Since thermoplastic molding requires cooling the material in the mold, temperature control is typically achieved with circulating oil or water. Thermoplastic mold temperatures are commonly less than 170 F. For LSR, the mold must be heated to 320 to 420 F to cure the material, most commonly with electrical cartridge heaters.

TOOL & PART DESIGN DIFFERENCES

We receive many requests for LSR tooling quotes on parts that use design standards from thermoplastics, such as drafts. LSR is flexible, and some of the features intended to facilitate thermoplastic part removal are not required. What is required is for parting lines to allow good venting or shut-off areas if we are molding onto a substrate. This is why it is highly suggested to involve your moldmaker in the product development phase.

A good example of a project where it is extremely important to involve your moldmaker early in the product design phase is a two-shot application for molding LSR onto a thermoplastic substrate or one grade of LSR onto another LSR. Such products typically require many little tweaks to allow a more userfriendly mold design and molding process.It is critical on two-shot applications to ensure we have proper shut-offs, proper venting, proper gate locations, and most importantly proper pairing of substrate and overmold materials. A thermoplastic substrate resin will need to withstand the mold temperature of the LSR half. If the thermoplastic starts to deform at a temperature below the LSR cure temperature, the project will fail. Another consideration that needs to be discussed early on is the method of bonding to the two materials. Are we using a self-bonding LSR or a mechanical bond—or both? These items will affect the mold concept. We all know the difficulty of changing a product print once it has passed all the approvals—so discuss these factors early on.

COLD DECK VS. HOT RUNNER

Both thermoplastics and LSR can use runnerless mold designs—but with significant differences. Thermoplastics require a hot runner to keep the material “live” between shots, together with a cooled mold. LSR is the opposite—requiring a cooled runner to prevent curing before material reaches the heated mold cavity. (LSR can start to cure at room temperatures once the two reactive components are mixed together.) Engineering concepts are similar from the perspective of maintaining the material delivery system thermally separate from the mold proper.

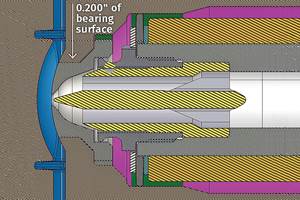

With LSR, the barrel on the molding machine and the cold deck (runner system) are kept cool using a water mixture. The typical temperature range of these components is 60 to 100 F. The most critical area is the contact point between the cold-deck nozzle and the mold—typically using a needle-valve gate. If this area is not engineered properly you will have molding defects, such as a “wet” gate look due to the area being too cold or an extended gate due to the area being to hot. As molds become larger in size and higher in cavitation, the temperature sensitivity and outgassing tendency of LSR makes the challenges much more difficult. This is why most LSR moldmakers and molders prefer not to go beyond 64 cavities.

Note that the economic motivation to use runnerless LSR molds is even greater than with thermoplastics, for several reasons. First, because cured LSR runner scrap cannot be reused. Second, because LSRs tend to be premium-priced materials. And third, because LSRs generally require longer cycles for curing than thermoplastics need for cooling. In molding small LSR parts, the runner can be thicker than the part, so the molder would be waiting for the runner to cure after the parts themselves are ready to demold. In addition, hot-runner LSR systems are more difficult to automate since they require removal of both the molded parts and the runner waste. That waste also has to be collected and eventually removed from the molding area. Molders often forget to include the cost of LSR waste generation and removal from the overall cost of a project.

RFQ FOR LSR MOLDS

In past years, the company that molded the parts had experienced personnel that could provide a mold quote and piece price to bid for a job. Most often these days, molders that have an opportunity to quote an LSR product will go to the moldmaker to provide a mold quote instead of asking internal personnel to quote tooling.

Today’s market challenges the moldmaker to provide a mold quote within two or three days, usually based on very limited information. Incomplete information provided at the time of quoting can cause later pricing issues. We have had instances where molders request a certain amount of cavities and we later find out that they don’t have a press big enough to run the mold. Critical information can be omitted—such as customers forgetting to inform us whether they want full automation or not. Part prints provided are sometimes not complete or the latest version of the design. Sometimes prints are not fully legible. All these variables take extra time and add to quotes that may not be complete and accurate.

Does your moldmaker have the personnel to provide this quoting service in a timely manner and with a tolerable level of accuracy? Do they have the experience and knowledge to ask the proper questions during the quoting stages? Are they willing to ask whether alterations can be made to provide a more robust process?

Molders used to working with thermoplastics might think there are hundreds of moldmakers throughout the world that can build a high-quality LSR mold. In actuality, there are only a few that can meet the criteria mentioned above. North America is fortunate to have several of these.

For the reasons discussed above, we strongly recommend working with an established moldmaker who understands rubber tooling and who works with LSR on a regular basis. The same applies to the injection molding machine and the meter-mix unit that goes with it. Even though many people would say the mold is the most important component in a molding process, a successful LSR project requires all four key elements: good material, good meter-mix unit, good molding machine, and a great mold. If the process needs automation, an appropriate support company also needs to be included.

It is our experience that the moldmaker should have the ability and personnel to project manage a complete turnkey project. The moldmaker should also have the space to allow the complete project to be assembled and tested in its facility. Even if just building the mold, the toolmaker has to have the molding equipment available to test the mold prior to shipment. Even the best mold-design concept can have processing issues that require some mold changes. To do this efficiently, trial testing should be done on all tooling prior to shipment. Time to market for most products is critical, so anything that can be accomplished at the tooling source to reduce the timeline can mean dollars saved for the customer.

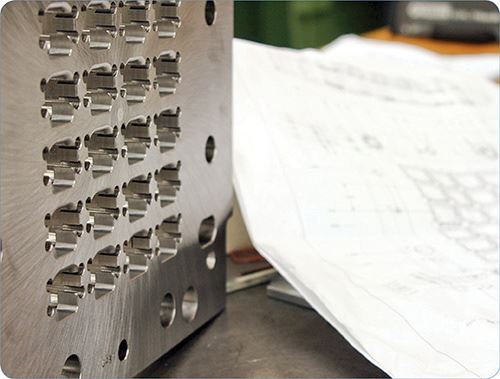

For that reason, it is important to evaluation the reaction time of a tooling source when it comes to making design changes. Ask whether a prospective moldmaker has the personnel and equipment to make these quick adjustments. Also consider whether the moldmaker has the precision measuring equipment needed to deliver tolerances in tenths and millionths of an inch for a quality LSR mold. Does the moldmaker follow defined processes that ensure consistency from one cavity to another?

All quality moldmakers have craftsmen that can make tooling. It’s their attention to detail and quality of their machinery, measuring equipment, and organization that will make the difference.

Related Content

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

Getting Into LSR: Part II--Chosing an Injection Machine

The criteria for selecting a liquid silicone rubber injection molding machine are very similar to selecting a machine for standard thermoplastic injection molding, with several key differences.

Read MoreGetting Started in LSR: Understanding the Materials, Part I

Liquid silicone rubber (LSR) injection molding is a long established process but it is enjoying an upsurge in interest for medical, automotive, infant care, and general industrial applications.

Read MoreLSR Part III-- Choosing a Mixing/Metering System

Liquid silicone rubber (LSR ) is a two component reactive chemical with a viscous, paste-like consistency.

Read More