Powder coating is the finishing process of choice for companies looking to reduce their environmental impact.

Photo Credit: Getty Images

Powder coating has long been the green process of choice for finishing operations. It produces less waste than alternative finishing processes such as liquid coating, and overspray is often able to be reclaimed and reused. Moreover, powder coating lines do not require the use of solvents, emit no volatile organic compounds (VOCs) and can operate with reduced energy, faster curing and lower temperatures. Now, with a range of powder coatings made using post-industrial recycled plastic, Sherwin-Williams aims to make a green finishing process even greener.

The Powdura ECO line from Sherwin-William’s General Industrial Coatings division (Minneapolis, Minn.) was the first powder coating on the market that is made using recycled content. Sherwin-Williams designed Powdura ECO to be transformative for both the company and the greater finishing industry. Tabitha McLeish, the company’s global marketing director for powder coatings in the General Industrial division, says, “We’re making lasting changes to the powder coating market and the kinds of powder coatings that we develop.”

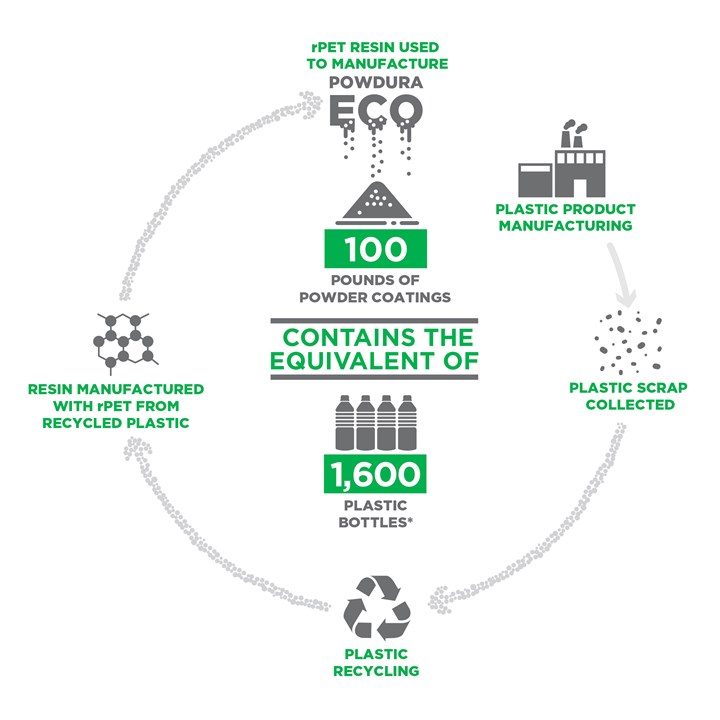

Powdura ECO is made from a resin that uses post-industrial recycled polyethylene terephthalate (rPET). On average, for every pound of polyester Powdura ECO produced, the equivalent of sixteen 16-oz. water bottles’ worth of plastic is recycled and repurposed, which keeps it from eventually ending up in landfills or polluting the ocean. McLeish says, “We're committed to having a positive impact on the planet, and sustainability is really a part of our innovation and new product development process—it’s one of the key drivers.”

Formulating an eco-conscious powder coating

Sherwin-Williams conceptualized the Powdura ECO range to offer a more sustainable alternative to conventional polyester powders. Sustainability is an innovation driver for the coatings industry, and it is a primary focus for Sherwin-Williams. “Our ultimate goal,” McLeish says, “is to bring differentiated products to the marketplace that help protect or benefit the planet in some way without sacrificing performance.”

When developing Powdura ECO, Sherwin-Williams and its supplier partnered to determine exactly how much rPET could be used in the resin that creates Powdura ECO to ensure it meets quality and performance standards, which is a key focus for many manufacturers about using recycled materials. In working with the company’s raw materials supplier, Sherwin-Williams’ research and development team determined that 25% was the optimal percentage of rPET that could be present in the resin while still maintaining or improving the quality, performance and aesthetics of the finish.

Each pound of Powdura ECO polyester coating is said to contain the equivalent of sixteen 16-oz. plastic bottles. The recycled plastic is used to manufacture a resin that goes into the powder coating. Photo Credit: Sherwin-Williams

The final product is a powder coating that McLeish says exhibits performance “identical to or better than Sherwin-Williams’ standard coatings.” It is said to have excellent color retention and solvent resistance, and, according to the company, can offer increased flexibility and impact resistance compared to traditional polyester powders. McLeish says, “I believe this is a lasting change that is really going to stick with the market and continue to grow at an exponential rate.”

Bringing Powdura ECO to market

The first launch of the Powdura ECO line includes both polyester triglycidyl isocyanurate (TGIC) and TGIC-free, as well as epoxy-polyester hybrid formulations. The coating comes in a variety of finishes, colors and special effects. In addition, Powdura ECO can reportedly align with standards including GreenGuard, LEED and BIFMA Level.

Powdura ECO is currently available in TGIC, TGIC-free and epoxy-polyester hybrid formulations. It is designed to integrate seamlessly into existing powder coating operations. Photo Credit: Shutterstock

Sherwin-Williams designed Powdura ECO to be an easy switch for manufacturers that are considering implementing sustainable practices into their powder coating lines. “It doesn’t require any other specialized application equipment to apply the coatings,” McLeish says, “and it behaves identically to the baseline formulas.” In short, it was explained that anything that can be powder coated with conventional polyester coatings can also be coated with Powdura ECO without sacrificing anything.

Powdura ECO is targeted at finishers across the industry, from OEMs to job shops large and small. The TGIC and TGIC-free coatings are said to be suited for internal and external applications including lawn and garden, transportation, consumer goods and light-duty building products. “It can be used on just about any metal substrate or product,” McLeish says. “The polyester TGIC and TGIC-free lines are standard durable and can be used outside for up to a year while maintaining market-acceptable color and gloss retention.” The epoxy-polyester hybrid option is more suited for materials handling equipment, large metal office furniture and fixturing in stores and retail spaces.

According to Sherwin-Williams, using a sustainable powder coating should enable manufacturers to differentiate themselves from their competitors and appeal to consumers, who are placing increasing importance on sustainability when making purchases. McLeish says, “All sorts of corporations and countries even are really stepping up to that sustainability piece. They are making ambitious goals and doubling down.”

Sherwin-Williams hopes the changes will be evident to consumers as they shop for new products. Each product coated with Powdura ECO will now have an eco-conscious origin story behind it. McLeish says Powdura ECO should “appeal to consumers who are starting to notice the impact that their choices have on the environment around them.”

Pushing more finishing processes toward sustainability

Powdura ECO came to market in early 2020, and it has already impacted how Sherwin-Williams plans to approach its existing product range. In addition to polyester TGIC and TGIC-free and epoxy-polyester hybrid coatings, the company plans to expand the Powdura ECO lineup with more options for powder coaters.

Additionally, the company is considering other ways it can implement sustainable practices into its existing product lineup. The reception of Powdura ECO has encouraged Sherwin-Williams to take a look at ways to make its other products more eco-conscious as well.

Related Content

General Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

Read MoreNPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreDow, Circusil Collaborating on Silicone Recycling Facility

Dow and Circusil announced plans to construct a silicone recycling facility in Kentucky.

Read MoreRead Next

Non-reactive Cleaning for Powder Coating

Northeastern Ohio industrial hinge manufacturer Midlake Products & Mfg. Co. recently added a powder coating line to its operation after years of contemplation. One deciding factor was a phosphate-free, non-reactive cleaning process.

Read MoreTGIC Powder Coatings vs. Non-TGIC Powder Coatings

As raw materials become increasingly scarce, powder coating consultant Rodger Talbert offers insights into using non-TGIC products.

Read MorePowder Coating and Green Building

How powder coating can aid architectural applications in achieving environmental certifications.

Read More