Articles

The Scale-Up Conundrum

There are many methods used to determine scale-up based on output, but most designers do not scale the melting requirement along with the output.

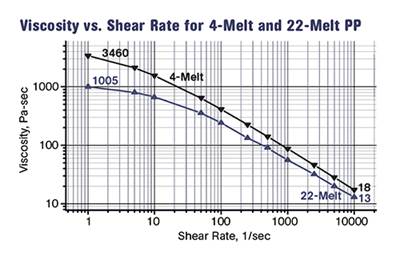

Read More‘Auto Compensate’ Your Press To Handle Viscosity Variations

Here's how to put your injection molding machine on cruise control to make consistently good parts even in the face of material viscosity variations.

Read MoreMelt Flow Rate Testing – Part 2

To fully appreciate the strengths and weaknesses of the melt-flow-rate (MFR) test it is important to know something about the way the test is performed.

Read MoreKnow Your Mold-Building Terminology

This can be particularly important when specifying a conformal-cooled mold.

Read MoreBusting the Conformal Cooling Myths

Conformal cooling is opening up new ways of doing things with new tools to solve problems.

Read MoreFrequently Asked Questions About Purging

This 'FAQ' sections answers common questions about how to choose and use purging agents.

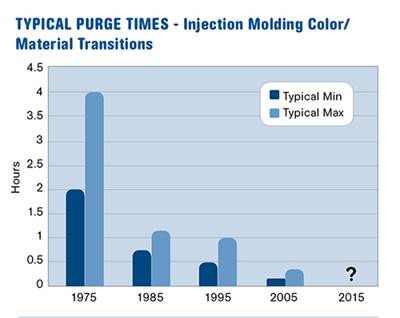

Read MoreNot Your Father’s Purging Agent

There are two important messages for today’s processors with regard to purging. First, as we near the peak of the “rapid improvement” stage of purging technology, the products now available are not the same old purging compounds of the past. Second, the “low-hanging fruit” has been picked—future technical improvements will likely be incremental and future improvements in productivity will require a shift in focus, toward transition planning and process optimization.

Read MorePurging High-Performance Engineering Resins

One of the fastest growing markets for commercial purging compounds is purging high-performance engineering resins. It is also one of the most difficult challenges, since both mechanical and chemical purging compounds have limitations when it comes to heat stability, residence time, flow restrictions, etc.

Read MoreArkema Launches Amorphous & Crystalline PEKK

WEB EXCLUSIVE: Arkema has introduced a comprehensive range of PEKK (poly ether ketone ketone) comprised of three families of high-performance thermoplastics for aerospace, oil exploration, and electronics applications.

Read MoreTPV Used for Robotic Extrusion of Automotive Seal

WEB EXCLUSIVE: Windsor Mold Group (WMG) is using ExxonMobil’s Santoprene TPV to replace EPDM rubber, allowing robotic extrusion of the bulb seal directly onto a PP cowl for Ford’s C-Max hybrid electric vehicle.

Read MorePEEK Chosen for Nuclear Reactor Seals

WEB EXCLUSIVE: Victrex PEEK was selected by EGC Critical Components for a seal system designed to prevent nuclear reactor coolant leaks during an emergency shutdown.

Read MoreIneos & Sasol Joint Venture for U.S. HDPE Plant

WEB EXCLUSIVE: Ineos Olefins & Polymers and Sasol North America are building a world-scale HDPE plant that will produce nearly 940 million lb/yr of HDPE using Ineos’ Innovene S bimodal slurry technology by the end of 2015.

Read More