Articles

New Device Senses Extrusion Melt Pressure Directly

A new type of melt-pressure sensor from Dynisco Plastics, Franklin, Mass., is said to be the first such device to sense pressure directly, without using mechanical structures or liquid-fill media.

Read MoreKraussMaffei Group Sold to Investors

In late September, Onex Corp., a Toronto-based private-equity firm, agreed to acquire the KraussMaffei Group of Germany for around $735 million from Madison Capital, which had owned KraussMaffei since 2006.

Read MoreMack Puts It All Together

To be “more than a molder”—it’s an ambition held by many top plastics manufacturers.

Read MoreThe New Lightweights: Injection Molded 'Hybrid' Composites Spur Auto Innovation

A thermoplastic composite technology that emerged just a couple of years ago promises to make dramatic strides within the next two years in automotive mass production of structural components.

Read MoreISO Poly Avoids Economic Woes With High-Value Films

Positioning itself on the high end of the blown-film market helped insulate this blown film processor from the recent economic downturn.

Read MoreStop Those Drooling Dies

Die drool, or plateout, can cause a host of problems for extrusion processors. Here is how to stop the problem before it starts.

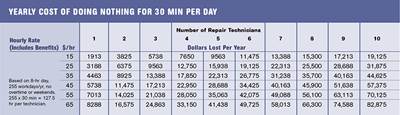

Read MoreUnderstanding Gravimetric Blender Accuracy & Payback

Accuracy is one of the least understood aspects of blending. The differences between batch and continuous blenders, how blend accuracy is calculated and controlled, which blender type is more accurate, how much accuracy is really required, and how payback is calculated are discussed here.

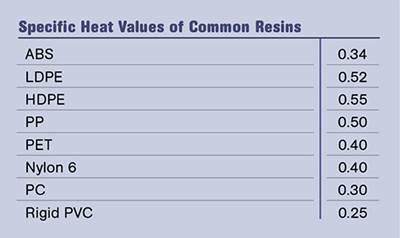

Read MoreWhat Output Should You Expect?

You can get a rough estimate of the potential output if you know the drive horsepower of your machine and the thermal characteristics of one of the materials you’ll be running.

Read MoreTop 10 Reasons Why Molders Fail At Implementing ‘Scientific Molding

What is Scientific Molding? And why do molders seem to have such a difficult time embracing its concepts? Here are some thoughts on the matter.

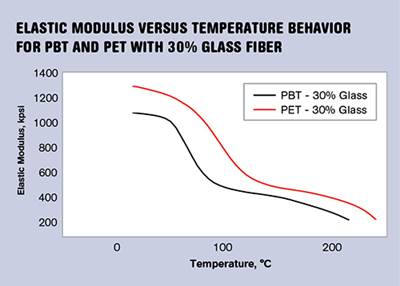

Read MorePBT & PET Polyester: Part 2 The Performance Factor

All things being equal, PET will outperform PBT mechanically and thermally. But the processor must dry the material properly and must understand the importance of mold temperature in achieving a degree of crystallinity that allows the natural advantages of the polymer to be realized.

Read More‘Light’ Grooves Offer Big Boosts in Film Processing

Blown film is main target for technology billed as an option to smooth bore feedthroats in extrusion.

Read More