Articles

More Effective Mold Maintenance: It’s All About the Data

When tooling issues are shutting down presses daily and you can’t muster the mold maintenance and operating records to figure out why, then like the song says, “Who ya gonna call?” The answer to that question proved crucial to Cosmetic Specialties International (CSI), LLC in Oxnard, Calif.

Read MoreOptimize Resin Management in Extrusion Blow Molding

In the EBM process, profits depend greatly on how judiciously you use resin.

Read MoreWhich Winder’s for You?

It's time to apply more science to the process of selecting the right kind of winder for your operation.

Read MoreMaintenance Training? Show Me the Money

Training works best if a goals are set and a plan is established to meet them.

Read MoreWhy I Still Like Analog Meters

They may not look as slick as their digital cousins, but I find them more helpful in identifying and troubleshooting extrusion problems.

Read MoreMinimize Screw Recovery & Cycle Times

There are hundreds of details you must identify and control to run a successful molding plant. One that is almost always at the top of the list is optimizing cycle time. Shorter cycles that make acceptable parts improve profits.

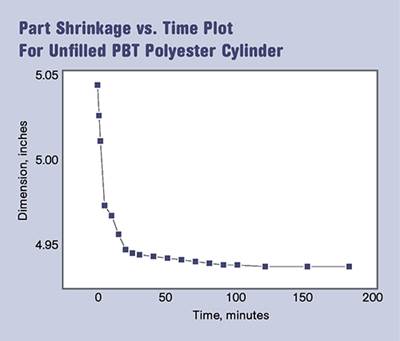

Read MoreDimensional Stability After Molding: Part 1

The degree to which molded parts shrink as they cool is largely dependent upon the composition of the material being processed.

Read MoreMaking the Value Connection In Proprietary Molding

“We make components that go into other devices.

Read MoreResin Prices Are on the Way Up

Higher prices are projected for PE, PP, PS, and PVC in this first quarter, driven by tighter availability and/or higher costs of feedstocks.

Read MoreLow Prices Won’t Last

2012 brought lower prices across the board to buyers of recycled materials.

Read MoreWeyerhaeuser & Ford Develop Cellulose-Fiber TP Composites for Automotive

WEB EXCLUSIVE: Forestry products producer Weyerhaeuser in Federal Way, Wash., has introduced a proprietary, patent-pending thermoplastic composite with cellulose-fiber reinforcement derived from wood.

Read MoreCopolyester Used in Pneumatic Tube Carrier

WEB EXCLUSIVE: A new application of proprietary Tritan copolyester from Eastman Chemical Co., Kingsport, Tenn., has been developed by Baltimore-based Pevco, a manufacturer of hospital pneumatic-tube delivery systems used to transport patient-critical materials between labs, pharmacies, blood banks, operating rooms, and emergency rooms. The new Pevco TEC-6 pneumatic tube carrier was designed specifically to be made with Tritan, according to Pevco’s director of product development and marketing Steve Dahl.

Read More