Conformal Cooled Sprue Bushings Line Expanded

PCS Company has added a 3/4-in radius for the U and B Series bushings options.

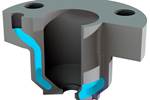

PCS Company has expanded its Conformal Cooled Sprue Bushings product line, which is designed to reduce cycle times for injection molders by providing for faster cooling of plastic sprues. Provided as direct retrofits to the common U (3/4-in diameter) and B (1-in diameter) series sprue bushings, the products are available in 8 (Model U) and 12 (Model B) standard sizes. PCS can also provide custom sized bushings for specific applications. These bushings are constructed of stainless steel for corrosion resistance and longevity.

Previously available in 1/2-in radius sizes, PCS has added the 3/4-in radius size options for both the U and B Series bushings. While cold sprue bushings often use straight-line cooling channels and require extended cooling times for the hot plastic to solidify, conformally cooled bushings use curved channels to improve cooling of the sprue, which PCS says reduces cycle times, increases efficiency, and provides better process control.

For easier ordering, PCS has updated its catalog pages with more information and updated CAD drawings. The company says it has also lowered prices.

PCS has added new standard sizes for its line of conformall cooled sprue bushings.

Photo Credit: PCS Company

Related Content

-

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.