Hot Runners: Valve Gate Nozzle Offers Greater Wear Resistance

Husky’s Ultra Helix 250 T2 targets small parts weights with difficult-to-access gate locations, promising less maintenance and more longevity.

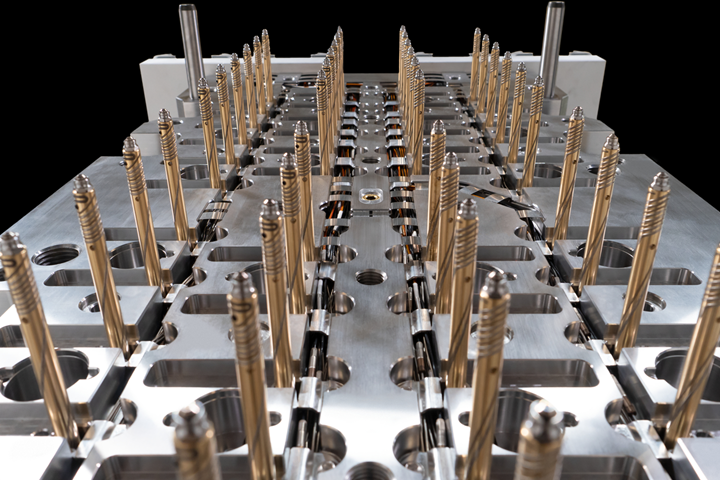

Originally introduced at K 2019 (read more in the Sept. 2019 Molds & Tooling K Preview), the Ultra Helix 250 T2 valve gate nozzle from Husky Injection Molding Systems extends that company’s Ultra Helix lineup. Husky has announced more technical details for the nozzle, which it says was developed to bring the benefits of its Ultra Helix technology to jobs with small part weights and hard-to-get-to gate locations.

The Ultra Helix 250 T2 has a 12-mm nozzle bore and pitch spacing down to 15 mm, enabling high cavitation density in a small mold footprint. The system utilizes a new stem-actuation design. PX actuation has the same diameter as the SX version, but is engineered specifically for polyolefins and will be standard on the U250 series nozzle.

Pneumatic-, plate- or servo-driven actuation are available. If the individual pneumatic option is chosen, pitch spacing is available down to 25.4 mm. Users can individually access valve stems without removing the backing plate, easing maintenance. The plate-actuated UltraSync-P or servo driven UltraSync-E options can achieve 15-mm pitch spacing.

Since the Ultra Helix 250 T2’s launch, Husky notes they’ve been applied in a variety of applications, ranging from medical barrier closures and flow regulation valves to personal care products, food and beverage packaging and flip-top closures.

Part weights from less than 0.1g to more than 4g and are being molded from resins typically prone to leakage, including PP, HDPE, LDPE, TPE and TPV. The valve gate nozzles have been applied in single and multi-material injection parts. To help prevent extended downtime caused by a material leak, Husky notes that it added a stem seal and utilized what it calls enhanced thermal management heater technology.

Husky’s Ultra Helix 250 T2 can achieve high cavitation thanks to tight pitch spacing.

Related Content

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.