Victrex USA Inc.

300 Conshohocken State Rd. Ste. 120

West Conshohocken, PA 19428 US

800-VICTREX | 484-342-6001

victrex.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Victrex USA Inc. Supplies the Following Products

- Polyetheretheketone (PEEK), Polyetherketone (PEK) and Other Polyketones

Editorial, News, and Products

-

Tracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.

-

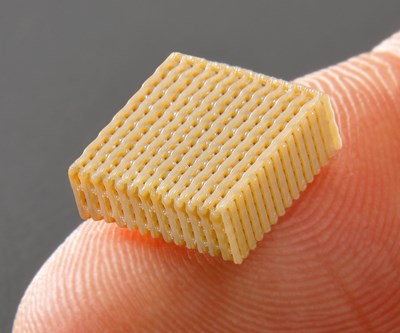

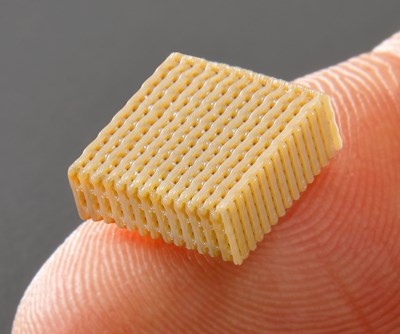

Materials: New PAEK Filament Optimized for Additive Manufacturing

Chinese 3D printing manufacturer INTAMSYS becomes the first reseller of Victrex’s new AM PAEK for 3D printing.

-

Cryogenic Victrex PEEK Outperforms Fluoropolymers in Oil & Gas Cryogenic Sealing Applications

AEV opts to use Victrec CT polymer for its cryogenic and severe service ball valves due to improved sealing reliability that meet the needs found in compressing and liquefying natural gas.

-

Victrex at K 2019: Innovating with PEEK

Expansion of Victrex’s PEEK portfolio ranges from 3D printing and films to composites, gear solutions and a food-grade family.

-

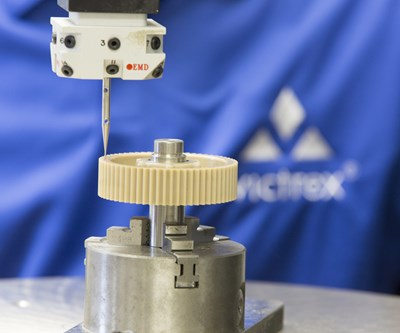

Materials: Victrex Awarded Key Automotive Quality Standard for Manufacture of Gears on Display at K 2019

USA design and manufacturing facility proves performance power with PEEK-based gears available for both ICE & electric powertrain platforms.

-

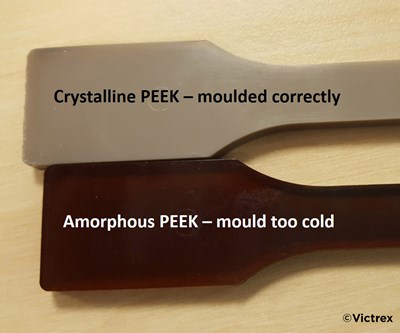

Five Factors to Consider When Molding PEEK

Are you a first-time molder of PEEK? Have you tried molding it and might be running into trouble? Take a look at five factors in the injection molding process that can help to avoid the need for troubleshooting when molding PEEK.

-

Victrex PAEK Used to Make One-Piece Fitting for Ultra-High Pressure Liquid Chromatography Systems

Swiss manufacturer VICI first to offer multi-use thermoplastic fitting that also allows easy handling and greater flexibility in the higher-pressure range.

-

Victrex to Make Multi-Million Euro Investment in Bond 3D Technology

Victrex and Bond will initially focus their new collaboration on demonstrating the potential in the spine and the semiconductor segments.

-

Materials: 'Cryogenics' Polymer for Energy Industry

High-performance PEEK Victrex CT200 targeted to dynamic sealing applications in the storage and transportation of gases at extremely low (cryogenics) temperatures.

-

Victrex Develops PAEK for Additive Manufacturing; Leads Consortium for Advancing AM Technologies

New generation materials rival earlier versions for both laser sintering and fusion filament fabrication processes.

-

News in TP Composites At JEC 2017 Show

Thermoplastic composites were a large part of the innovations on display in Paris.

-

Highlights of Thermoplastic Composites at JEC 2017

No shortage of new developments in thermoplastic composites at the big show.

-

No News Shortage on Thermoplastic Composites at JEC World 2017

Sabic enters continuous carbon-fiber reinforced tape; TxV taps Fiberforge technology; Xenia introduces materials reinforced with hybrid (glass/carbon) fillers; and more.

-

Victrex Expands Its “Downstream” Parts Manufacturing Business

The joint venture with Tri-Mack Plastics to accelerate use of PAEK composite components in aerospace.

-

K 2016 Preview: Materials & Additives

Driving the wide range of new developments in engineered plastics and additives are higher performance, safety, and sustainability.

-

3D Printed PEEK-Based Composite Pipe for Subsea Oil & Gas Use

Magma Global's flexible m-pipe technology used for the largest and longest Victrex-based PEEK structure achieved to date.

-

Victrex Invests in PEEK Composites

To support industrial and medical sector applications, Victrex embarks on downstream manufacturing projects for UD tapes and composite plates..

-

Carbon Fiber PEEK Replaces Metal in Aircraft Door Fitting

Victrex's 40% carbon fiber-reinforced PEEK results in a 40% savings in both weight and production costs over the incumbent aluminum part.

-

Victrex Acquires Kleiss Gears to Bolster PEEK Gears Growth

PEEK resin producer buys specialist in injection molding gears.

-

Victrex Acquires Kleiss Gears to Bolster PEEK Gears Business

Victrex, West Conshohocken, Penn., has enhanced its ability to provide complete ‘integrated’ service through its acquisition of PEEK polymer gears specialist Kleiss Gears, Grantsburg, Wisc.

-

Advanced Hybrid TP Composite Molding for Aerospace

Overmolding PEEK onto PAEK laminate.

-

PEEK Featured In New Line of Subsea Connectors

Victrex's PEEK is the overmolded insulating material in a new line of highly-efficient connectors for subsea and downhole applications.

-

PEEK Used In Overmolding Transmission Components Of All-Terrain Vehicle

Replacing a coated brass gear, is Victrex's PEEK compound in the robust overmolded steel drive shaft segment gear of BPG Werks all-terrain, dual-tracked vehicle

-

K 2013 Preview: Materials & Additives

The K 2013 show will present a broad range of engineered plastics materials, including thermoplastic composites, as well as additives. Automotive and electronic applications will be the main targets, as well as medical, packaging, lighting, and construction.

-

PEEK Chosen for Nuclear Reactor Seals

WEB EXCLUSIVE: Victrex PEEK was selected by EGC Critical Components for a seal system designed to prevent nuclear reactor coolant leaks during an emergency shutdown.

-

PEEK Mesh for Filtration in Harsh Environments

WEB EXCLUSIVE: Dexmet Corp., Wallingford, Conn., a manufacturer of precision expanded metals, foils, and polymers has added Aptiv film to its PolyGrid portfolio, which is made of Victrex PEEK from Victrex USA, West Conshohocken, Pa.

-

High-Flow PEEK Makes Small, Intricate Pipette Tips

WEB EXCLUSIVE: An unfilled grade of Victrex 90 Series high-flow PEEK from Victrex USA was used to mold small medical pipette tips.

-

Four Key Markets Drive Material Advances At K 2010

Last fall’s K 2010 fair in Germany drew dozens of materials suppliers to show off hundreds of new products, aimed especially at packaging,medical, automotive, and electrical/electronics.

-

Materials at NPE 2003

The footprint of thermoplastic materials suppliers at this year’s NPE is going to be fainter than usual.

-

Extreme Plastics New Contenders Push Limits Of Heat and Chemical Resistance

The top of the thermoplastic performance pyramid is growing more crowded and more finely differentiated due to heightened demand for lighter, tougher alternatives to metals, ceramics, and thermosets.

-

Medical Tubing: Tinier Than Ever And Much More Complex

Medical tubes are becoming ever smaller and thinner while adding new features like high-tech material combinations, more wire braiding/wrapping, and heat-shrink sheathing for strength and kink resistance.

-

New 'Ultra' Thermoplastics Contend for Top of Performance Pyramid

The industry’s broadest line of highly heat- and chemical-resistant thermoplastics is being fortified with several new amorphous and crystalline materials in the so-called “ultra-performance” category.

-

K 2004 Wrap-Up on Materials: Setting New Benchmarks for Processability and Performance

Higher flow, higher heat, higher barrier, higher clarity, higher stiffness, lower durometer, lower smoke, lower odor—materials exhibits at the recent K 2004 show in Dusseldorf were stretching the bounds of processing and performance properties in all directions.

-

K 2004 News Preview: Materials

Quite a few new polyolefins are being featured at this year’s show, with a particular emphasis on specialty PP and PE materials.

-

New Twist in Thermoplastic Composites Makes High-Strength, Net-Shape Fasteners

A Swiss manufacturer of aerospace, automotive, and medical parts has developed a novel compression molding process that delivers net-shape thermoplastic composites with strength per unit weight reportedly competitive with those of machined steel, aluminum, and titanium.

-

Demand Surge Tightens PEEK Supply

The pace at which polyketone materials are replacing metals shows no sign of abating. Indeed, PEEK's potential in fuel cells, plus accelerated applications development in existing markets, suggest that supply tightness could persist through 2003, when more new PEEK capacity is expected to bring relief.