Extrusion

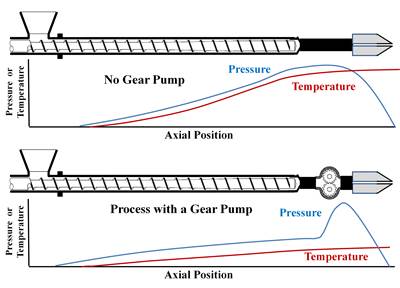

Is a Gear Pump Right for Your Single-Screw Operation

As with everything else, there are pros and cons, but more of the former. They provide processors higher rates while decreasing the temperature of the extrudate while enabling downgauging.

Read MoreDavis-Standard Expands Global Service Capabilities

Enhanced capabilities are designed to support all equipment manufactured by Davis-Standard and its subsidiaries.

Read MoreElectric Roller Suited for High-Temp Web Applications

Billed as “game-changing” product to enhance process control and efficiency.

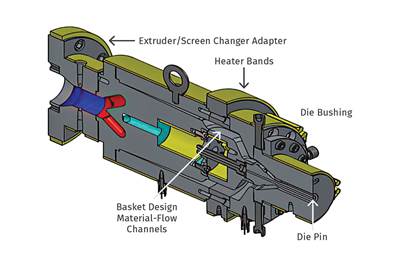

Read MoreHow to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

Read MoreLow-Smoke, Non-Halogen Polyolefinic Compound for Armored Cables

Avient’s latest addition to its ECCOH portfolio is designed to prevent environmental stress cracking in low- and medium-voltage cable sheathing.

Read MoreFiltration System Helps Film Processor Manage Recycled Material Mandates

Global film processor RKW teams with Nordson to enable it to process blown film with high recycled content.

Read MoreStop Shopping for a 'Jack of All Trades' Extruder

Some processors try to find “fits all” extruders to cover all processing possibilities. But you’d have to grossly overpower it to achieve this, and that’s expensive up front and will result in inefficiencies over time.

Read MorePFAS-Free Process Aid Eases Switch for Extrusion Processors

Aimed at blown film, pipe, and wire and cable, two grades are reportedly compatible with other additives used in these processes.

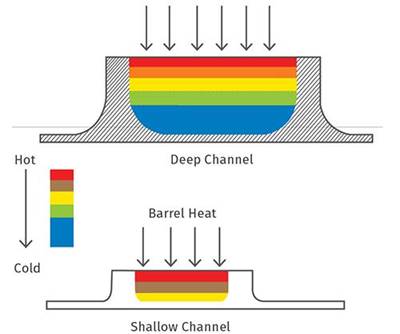

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreRohm, SABIC Combine on New Film, Sheet Unit

Called Polyvantis, new firm to be a global powerhouse in PC and PMMA extrusion.

Read More