Extrusion

NPE News in Extrusion

This NPE show won’t have a lot of extruders on the floor, either running or static. Instead, look for videos and announcements of new technology. You will also find lots of ingenious peripheral devices to improve output and quality and save resin. Some will do all three, and cost less into the bargain.

Read MoreANTEC at NPE: Editors' Picks

One of the unusual features of NPE 2009 in Chicago June 22-24 will be the first-ever concurrent presentation of the SPE ANTEC conference, by far the largest of seven conferences at McCormick Place during the show.

Read MoreInternally Cooled Pipe Die Speeds Output, Reduces Stresses

The recently developed Internal Air Cooling Die from iBA GmbH in Germany substantially increases output of polyolefin pipe or correspondingly reduces the length of downstream cooling, the company says.

Read MoreKeeping Track of 4300 Products

Rowmark LLC in Findlay, Ohio, is an extruder of specialized sheet materials for engraving, architectural signage, awards, and identification.

Read MoreNPE 2009 News Flash

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

Read MoreInternal Benchmarking: Setting Targets

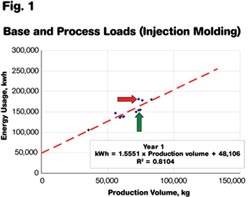

Last month, we discussed how to graph your plant’s “process energy fingerprint.” Now we’ll show you how to make use of that information.

Read MoreNovel Melt Blending Technology Commercialized in Micro- and Nanolayer Films

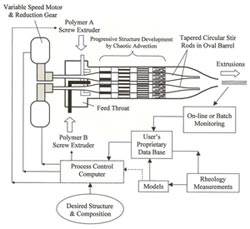

The first two commercial devices have been installed to melt blend two or more polymers using a structured fluid-dynamic mixing process known as “chaotic advection.” This process creates unusual micro-scale and nano-scale phase morphologies that potentially can optimize extruded film properties using fewer materials and extruders than with highly layered coextrusion.

Read MoreWhat’s Your Process Energy Fingerprint?

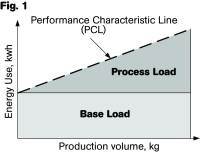

As we discussed in last month’s column, your plant’s “energy fingerprint” is composed of the base load and the process load.

Read MoreGloucester Engineering Teams Up With Kabra in India

Gloucester Engineering Co. in Gloucester, Mass., has formed a joint venture with Kolsite Group in Mumbai, India, to build blown film lines at Kabra Extrusiontechnik Ltd., a Kolsite company.

Read MoreKnow Your Plant’s ‘Energy Fingerprint’

It is commonly thought that energy use in plastics processing is fixed and uncontrollable.

Read More